We – EPG Team the largest Chain and agricultural gearbox factory in China with 5 distinct branches. For a lot more specifics: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

The merchandise properly shows environmental defense and strength conserving. 1 Our main merchandise are chain , gears, sprocket, Needle Roller bearings, Cylindrical Roller Bearings, Rod conclude Bearings, Spherical simple bearings, Observe roller Bearings for Guideway, Roller Bearings, Mix Bearings for forklifts, Water Pump Bearings, SNR Vehicle Bearings and all kinds of Spherical Bearings. element of our software consulting is that we have been collecting and combining the encounter in chain and sprocket apps in a variety of places for a long time. This is specifically fascinating for us each time buyers strategy us with some exceeding and demanding requirements. ISO 9001 qualified company of precision roller chains. Types contain one and a number of strand, hollow pin, side bow, rollerless, self-lubricating, straight sidebar, double pitch, brushed, nickel plated, armor coated, 304 stainless steel, leaf, hoist and O-ring, citrus, sorting and caterpillar roller chains. EPT 2480PMZ Multiflex EPT Chain with Different Thickness

| Identify |

Har2480PMZ |

Brand |

Hairise |

| Material |

Plastic |

Operate |

Conveyor |

| Certification |

ISO9001:2008 |

Pitch |

38.1mm |

| Kind |

Plate width(mm) |

Sideflex radius(mm) |

Bodyweight(kg/m) |

| Har-2480PMZ-K173 |

44. |

160 |

1.twenty |

Characteristic:

one: Application in the conveyor of tinplate bottle, the conveyor of PET bottle and the conveyor of aluminium pot, storage platform and conveying of edge. It is suitable for small things passing. It also suitable for the conveying of medication, cosmetics, and small meals .

2: The temperature of POM :-40°C~+90°C

3:The temperature of PP:+1°C~+98°C(suited for the atmosphere of sour)

This sort of modular belt can be utilized in pursuing industries:

- Market application: tobacco market, logistics market, glass market, drugs and chemical business.

- Fruit & vegetable & dairy & apps: elevators, inspection tables and packaging traces

- Beverage market this kind of as acceleration, beer, comfortable drink, milk and accumulation.

- Bakery purposes: raw dough managing, cooling lines and packing traces

- Meat sector this sort of as tray pack line and metallic detectors.

- Food sector this sort of as cool off traces and pack lines.

- Can creating/filling traces and accumulation tables

- Spiral purposes as proofing and freezing

- Meat & poultry apps: packaging strains

- Seafood applications: tray packing lines

- EPT fields associated to plastic modular belt.

Firm Profile:

Mujia EPT Technological innovation (ZheJiang ) Business Restricted

Established in the year 2004, we are engaged in supplying a huge variety of finest EPT Slat Chain, Straight Running Chain, Stainless Steel (SS) Slat Chains, MS Chains, Flexible Plastic Chains, Roller Chains, Finger Chains, Modular Plastic EPT Belts, EPT Use Strips, Corner tracks, EPT Moulded Sprocket and all types of conveyor Parts, chain conveyor, chain community conveyor, steel mesh conveyor, roller conveyor, belt conveyor, improve conveyor, screw conveyor, inclined conveyor and so on. Please re EPT confident that customise is also available.

EPT EPT shows a vanguard and full higher-good quality product portfolio for bottling, packaging, glass, logistic, foods, beverage, bakery. Dairy, fruit, vegetable, meat poultry, seafood, Tobacco, medication, chemical business and can production applications.

Our goods handed ISOISO9001 international high quality method authentication, CE, Fda, SGS and so on. During the producing of our current variety quality inspectors make certain that the generation process and the supplied concluded variety satisfies essential good quality stHangZhourds. On the basis of mutual gain, we will fulfill your requirements with adequate stock, realistic price tag and complete services techniques.

Our merchandise are extremely well-known in a lot of international locations, these kinds of as The usa, Britain, Italy, Russia, France, Poland, Spain, France,Thailand, Australia, Bangladesh, Brazil,Canada, Chile, Denmark, Egypt, Finland, Germany, Ghana, Greece, India, Indonesia,Eire, Japan, Korea, Kuwait, Mexico, Morocco, Netherlands,Pakistan,Sweden,Turkey, United Kingdom, Venezuela, Vietnam, Vietnam and so on.

Main solution:

Slat top chain:

Massive variety of straight managing and facet versatile chains, offered in steel or thermoplastic resources, enabling answer for any software

Stainless metal and plastic slat best chains, rubber leading chains, roller best chains.

Modular belt:

Comprehensive variety of modular belts and chains, provided in distinct pitches (from 8 mm pitch to 2″) and leading floor execution, to match any application

Flat Prime Belt has a easy surface without holes (utilised to transportation general merchandise).

Perforate Flat Best Belt has an all round appearance equivalent to the flat top but has a slot gap for ventilation and liquid.

Flush Grid Belt is generally used in creation lines that call for cleansing of materia EPT and for cooling. There are openings> twenty% of the belt spot. Developed to drain h2o and air

Elevated Rib Belt. There are thin ridges along the longitudinal belt of some designs. Put on a Finger Plate to link amongst the belts. Which the skinny ridge elevated Is to reduce the friction of the content with the belt area

Rubber Prime Belt is the use of rubber (Rubber) to be connected to the belt. To help prevent slipping of the substance even though conveying in a vertical position

Roller Prime Belt is utilised to express and modify the direction of the packing (Sorting) of the package deal.

Multi Leading EPT Chains:

– Desk Prime Chains, Steel Slat Chains, Facet-flex Chains, Roller Leading Chains, Snap-on Chains…

• Mat Leading Modular Belts:

– OPB MPB Series Belts, R Collection Modular Belts, 900 Sequence Modular Belts, Rib Top Belts ARB

• Steel Roller Drive Transmission Chains

– EPT Roller Chains, Stainless Carbon Metal Roller Base Chain ANSI 60 12A 40 08A.

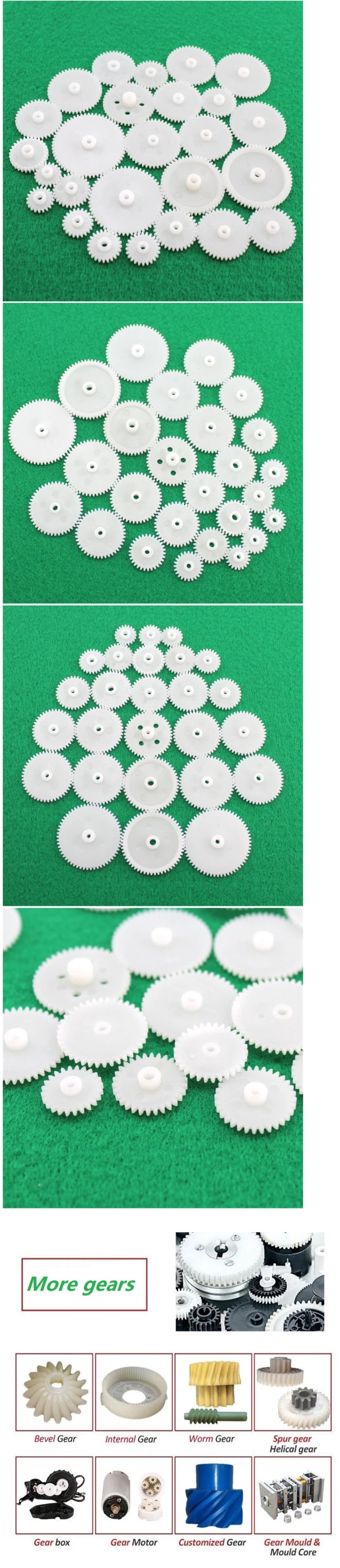

Sprocket:

Available in moulded and machined variations, sound and break up

Personalize for Tooth variety, DF and outer diameter is accessible.

EPT Components

Frame Assistance Bases, Mounting Brackets, Xihu (West Lake) Dis. Rail Bracket Clamps, Chain Belt Sprocket

– Connecting Clamp Joints, Photocell Sensor Clamps, Cross Clamp Connector, Leveling Feet

– Chain Xihu (West Lake) Dis. Rail Profiles, UH EPT PE Put on Strips, Chain Tracks Slides, Custom Made Components

product handling and supporting components

Corner tracks: Magnetic, TAB, Bevel curves, and Reduced pin center curves, each stHangZhourd and custom made-manufactured

Conveyor:

Plastic flexible chain conveyor, chain conveyor, chain network conveyor, metal mesh conveyor, modular belt conveyor, PVC/PU conveyor, roller conveyor, straight conveyor, curved conveyor, double rail conveyor, update conveyor, screw conveyor, inclined conveyor, push roller conveyor, gravity roller conveyor, and driven idler roller conveyor.

The Use of Modular Conveyor Belt Components:

1. Modular conveyors transportation materia EPT from one spot to another.

two. Sprocket functions as a belt travel equipment.

3. Wear Strip is to assistance the belt from make contact with with the framework to decrease friction.

4. Steel supports the Put on Strip

five. Sq. shaft to push the sprocket

six. The motor acts as a power transmission for the technique to operate.

The composition of the conveyor system can be equally steel and Stainless, relying on the environment that the person needs.

Why decide on Us:

EPT is quite very pleased to declare that all its POM (acetal resin) EPT products are made with homo-polymer POM provided by DuPont.

Solution lifecycle in EPT is structured according to the ideas of Total Quality Management (TQM), with a solid historic dedication toward a steady improvement method across all our operations, fostering the prolonged-term success of the organization.

EPT all round item assortment is completely made in residence in purchase to guarantee continuous greatest End-to-Finish control of the product high quality throughout all the phases of the producing procedure. Steady prime-tier item good quality is more supported by historical partnerships of EPT with world-wide leaders in metal and plastics producing industries.

TQM in EPT stems from our enthusiasm for excellence and includes all users of our group, always actively included in improving procedures, products, services and the interior lifestyle.

Positive aspects of the EPT merchandise:

1. Easy to clear, effortless to put in.

two. Special types give excellent grip on inclination.

three. Rugged, high strength – low extend attribute.

four. Low functioning sound and expenses, decreased routine maintenance, outstanding toughness.

five. Very good good quality with reasonable price, well timed delivery and wonderful customer support.

6. Ample shares for stHangZhourd factors, so we can satisfy your urgent wants.

7. Non-stHangZhourd is obtainable, we can personalize it according to your detailed specification.

eight. Full item line, our manufacturing facility can supply all types of products relate to conveyor.

9. Heat resistance, abrasion resistance, corrosion resistance, chemical resistance, Tremendous use resistance.

FAQ:

Q1. The place is your manufacturing unit found? How can I visit there?

A: All our clients, from property or overseas, are warmly welcomed to check out us. Before you check out our firm, we can link by cellphone! Our firm is found in ZheJiang , China, close to the ZheJiang Xihu (West Lake) Dis.ao Intercontinental Airport. And our manufacturing facility is in ZheJiang HangZhou, we will set up autos to there.

Q2. I never know what belt I currently use. Can you support me recognize my belt?

A: Our on-line belt identifier can help you slim down the series and design of your existing belt. If you need a lot more certain data on plastic conveyor chain belt components manufacturers, get in touch with me freely for plastic chains/ belts/ PU/PVC/Rubber belts/ EPT components and conveyors.

Q3. What can you do If the goods were damaged?

(1) If merchandise had been broken once you bought from me,I would substitute them freely according to the established photos.

(2) If the goods had been damaged when you employed, we could offer 5 year top quality guarantee for plastic conveyor chain belt parts manufacturers below typical working atmosphere.

Q4. Does EPT provide PDF information of goods?

A: Yes, in our obtain centre you can uncover PDF files for a large quantity of our items.If you can not find what you are seeking for, send me your reque EPT by electronic mail or speak to me on Wechat or Whatsapp freely.

The use of authentic products manufacturer’s (OEM) part quantities or trademarks , e.g. CASE® and John Deere® are for reference reasons only and for indicating merchandise use and compatibility. Our organization and the shown alternative areas contained herein are not sponsored, approved, or created by the OEM.