Product Description

1. Technical features

The high degree of modularity is a design feature of SKM, SKB series helical-hypoid gear units. It can be connected respectively with motors such as normal mtor, brake motor, explosion -proof motor, frequency conversion motor, servo motor, IEC motor and so on. This kind of product is widely used in drive fields such as textile, foodstuff, ceramice packing, logistics, plastics and so on.

1.1 Product characteristics

SKM SKB Seires helical gear units has more than 4 types. Power 0.12-4kw, Ratio 7.73-302.5, Torque max100-500 NM, Modulaw and multistructure can meet the demands of various conditions.

(1)Ground-hardened helical gears.

(2)Modularity, can be combined in many forms.

(3)Made of high-quality aluminum alloy, light in weight and nonrusting.

(4)Large in output torque, high efficiency, ene-rgy saving and environmental protection.

(5)The mounting dimension of SKM series are compatible with SMRV series worm gear unit(A part of SMRV050 dimensions are different from SKM28)

(6)The mounting dimension of SKB series are compatible with W series worm gear unit.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Function: | Speed Reduction |

|---|---|

| Layout: | Cycloidal |

| Hardness: | Hardened Tooth Surface |

| Customization: |

Available

|

|

|---|

Advantages and disadvantages of worm gear reducer gearbox

If you are looking for a worm gear reducer gearbox, you have come to the right place. This article will cover the pros and cons of worm gear reducer gearboxes and discuss the different types available. You will learn about multi-head worm gear reducer gearboxes, hollow shaft worm gear reducer gearboxes as well as hypoid gear sets and motors.

Hollow shaft worm gear reducer gearbox

Hollow shaft worm gear reducer gearboxes are used to connect two or more rotating parts. They are available in single-axis and dual-axis versions and can be connected to various motor types. They can also have different ratios. The ratios of these gear reducer gearboxes depend on the quality of the bearings and assembly process.

Hollow shaft worm gear reducer gearboxes are made of bronze worm gears and cast iron hubs. The gears are lubricated with synthetic oil. They are lightweight and durable. They can be installed in various engine housings. Additionally, these gear reducer gearboxes are available in a variety of sizes. The range includes 31.5, 40, 50, 63, and 75mm models. Other sizes are available upon request.

In addition to worm gear reducer gearboxes, there are also helical gear reducer gearboxes. These reducer gearboxes can achieve very low output speeds. They are also suitable for all-around installations. In addition, the advantage of a multi-stage reducer gearbox is that it is more efficient than a single-stage gear reducer gearbox. They also feature low noise, low vibration, and low energy consumption.

Hollow shaft worm gear reducer gearboxes are generally less expensive and last longer. They are also a suitable replacement for solid shaft gearboxes for machines that require high torque without compromising strength. Typical gear arrangements include worm, spur, helical and bevel gears. Gear ratio is the ratio of input torque to output torque.

Multi-head worm gear reducer gearbox

The multi-head worm gear reducer gearbox is used to reduce the speed of the machine. It uses friction to hold the worm in place while transmitting power. These gears can also be called ground worms and hardened worm gears. They are useful in conveying systems and most engineering applications.

Multiple worm reducer gearboxes have a large number of gear ratios. These gear designs have a central cross-section that forms the front and rear boundaries of the worm gear. This design is a better choice than other worm gears because it is less prone to wear and can be used with a variety of motors and other electronics.

Adjustable multi-head worm gear reducer gearbox to reduce axial play. Usually, the backlash on the left and right sides of the worm is the same. However, if you need less backlash, you can buy a double lead worm gear. This design is ideal for precision applications requiring small clearances. The lead of the opposing teeth of the double worm gear is different from the right side, so the backlash can be adjusted without adjusting the center distance between the worm gears.

Worm gear reducer gearboxes are available from a variety of manufacturers. Many gear manufacturers stock these gears. Since the gear ratios are standardized, there is no need to adjust the height, diameter, or length of the shaft. Worm gears have fewer moving parts, which means they require less maintenance.

Hypoid Gear Set

Worm gears are the most common type of gear. While these gears are great for high-to-low ratios, hypoid gear sets are much more efficient in all ratios. This difference is due to higher torque density, better geometry and materials, and the way hypoid gears transmit force differently than worm gears.

Hypoid gear sets have curved helical teeth. This results in smooth gear meshing and little noise. This is because the hypoid gears start to slowly contact each other, but the contact progresses smoothly from tooth to tooth. This reduces friction and wears, thereby increasing the efficiency of the machine.

The main advantages of hypoid gears over worm gears are higher torque capacity and lower noise levels. Although their upfront cost may be higher, hypoid gears are more efficient than worm gears. They are able to handle higher initial inertia loads and can deliver more torque with a smaller motor. This saves money in the long run.

Another advantage of hypoid gears is the lower operating temperature. They also do not require oil lubrication or ventilation holes, reducing maintenance requirements. The hypoid gear set is maintenance-free, and the grease on the hypoid gear set lasts for decades.

Hypoid gear motor

A hypoid gear motor is a good choice for a worm gear reducer gearbox as it allows for a smaller motor and more efficient energy transfer. In fact, a 1 hp motor driving a hypoid reducer gearbox can provide the same output as a 1/2 hp motor driving a worm reducer gearbox. A study by Agknx compared two gear reduction methods and determined that a hypoid gear motor produces more torque and power than a worm reducer gearbox when using a fixed reduction ratio of 60:1. The study also showed that the 1/2 HP hypoid gear motor is more energy efficient and reduces electricity bills.

Worm reducer gearboxes run hotter than hypoid gears, and the added heat can shorten their lifespan. This can cause components to wear out faster, and the motor may require more frequent oil changes. In addition, hypoid gear motors are more expensive to manufacture.

Compared to worm gears, hypoid gears offer higher efficiency and lower operating noise. However, they require additional processing techniques. They are made of bronze, a softer metal capable of absorbing heavy shock loads. Worm drives require work hardening and are less durable. Operating noise is reduced by up to 30%, and hypoid gears are less prone to breakage than bevel gears.

Hypoid gear motors are prized for their efficiency and are used in applications requiring lower torque. A unique hypoid tooth profile reduces friction. In addition, hypoid gear motors are ideal for applications where space is limited. These geared motors are often used with pulleys and levers.

R series worm gear reducer gearbox

R series worm gear reducer gearboxes have a variety of characteristics that make them ideal for different applications. Its high rigidity cast iron housing and rigid side gears are designed for smooth drive and low noise. It also features high load capacity and long service life. Additionally, it can be assembled into many different configurations as required.

High efficiency, large output torque and good use efficiency. It comes in four basic models ranging from 0.12KW to 200KW. It can be matched with right angle bevel gearbox to provide large speed ratio and high torque. This combination is also suitable for low output and high torque.

AGKNX Electric Worm Gear reducer gearbox

AGKNX Electric worm gear reducer gearboxes are available with NEMA C-face mounting flanges for a variety of motors. These reducer gearboxes feature double lip oil seals, an aluminum alloy housing, and two bearings on the input and output shafts. These reducer gearboxes are rust-proof and have epoxy paint on the inside. They are available in a variety of ratios, from 7.5:1 to 100:1.

Worm reducer gearboxes are one of the most cost-effective and compact gears. These reducer gearboxes increase output torque while reducing input speed. AGKNX Electric’s worm gear reducer gearboxes are pre-installed with Mobil SHC634 Synthetic Gear Oil. These reducer gearboxes have an internal oil gallery guide to protect the shaft. They also have a one-piece cast iron housing.

AGKNX Electric Corporation is the leading independent distributor of electric motors in the United States. They have eight strategically located warehouses, enabling them to ship most orders on the same day. They offer motors of various sizes up to 20,000 hp. They also offer a variety of motor controls and variable speed drives.

editor by CX 2023-05-18

China Competitive Quality WPEDKA Worm Gear Speed Reducers Gearboxes Gearmotor Planetary Hypoid Helical for industrial machines gearbox drive shaft

Warranty: 1 calendar year

Applicable Industries: Accommodations, Garment Shops, Developing Material Shops, Producing Plant, Machinery Mend Outlets, Foodstuff & Beverage Manufacturing unit, Farms, Restaurant, Residence Use, Retail, Foodstuff Shop, Printing Stores, Construction works , Strength & Mining, Foodstuff & Beverage Outlets, Promoting Business, Other

Weight (KG): forty KG

Custom-made support: OEM, ODM, OBM

Gearing Arrangement: Worm

Output Torque: 1.8-2430N.M

Input Velocity: 750-1500rpm

Output Pace: 14-280rpm

clolor: Blue/grey/yellow

Packaging Specifics: Cartons and robust wooden scenario for sea transporation

Port: HangZhou,ZheJiang

WP worm reducer:WP worm equipment and worm reducer is designed on the basis of wd reducer, the worm is created of forty five # higher good quality steel following heattreatment processing and producing, worm gear with tin bronze forged, dress in-resisting overall performance is good, specifically on thebearing ability is more apparent, is mostly utilized in plastics, metallurgy, beverage, mining, lifting transport, chemical reductiondrive development and other mechanical gear.WP worm reducer features:1, clean transmission, vibration, so that the influence and noise are tiny, deceleration ratio, wide flexibility, can be used withall kinds of mechanical products.2, can achieve a massive transmission ratio by single phase transmission, compact construction, most types of reducer has betterself-locking, braking specifications of mechanical tools can conserve the brake system.3. The meshing friction loss of worm screw tooth and worm gear tooth surface is massive, so the transmission efficiency is lowerthan that of the equipment, which is prone to heating and high temperature.4. Greater specifications for lubrication and cooling.5, very good compatibility, worm equipment and worm are produced in accordance with countrywide standards, bearings, oil seals and otherstandard areas.6. Kinds of box physique: standard kind (box body is vertical or horizontal composition with sole baseboard) and universal variety (box bodyis rectangular, with mounted screw holes on several sides, with no sole baseboard or with sole baseboard set up individually)7, the input shaft connection method has the basic variety (solitary input shaft and double input shaft), with 2 varieties of motor flange.8. The position direction of the output and enter axes is decrease and upper Output shaft up and down Input axis up and down.9. Two or 3 reducer sets can be employed to sort multi-phase reducer to acquire the highest transmission ratio. Packing & Supply Packaging: In get to guarantee the integrity of solution physical appearance, we will pick cartons, wood pallets and picket pallets in accordance to consumer needs. ●Delivery time: Each reducer is manufactured and analyzed in accordance with strict and fixed methods to make certain that the quality is right ahead of leaving the factory and shipping and delivery on time. ●Transportation mode: We will choose the most suited mode of transportation for our consumers in accordance to the weight and dimensions of the merchandise. We can also choose the mode of transportation according to the needs of our clients. ●Receiving and soon after-product sales service: Following receiving the products, remember to check whether they are in great problem. We will provide buyers with excellent after-product sales service. Organization Profile HangZhou SYS Transmission Co., Ltd. is a specialist producer of velocity reducer,gearbox, electric motor, gearmotor, screw jack, couplings and other transmission goods. With fast supply, superior following-sales provider, sophisticated creating facility, our speed reducer market nicely equally at home and overseas. We have exported reducers to Southeast Asia, Japanese Europe and Middle East and so on. Our intention is to produce and innovate on basis of large top quality, and create a very good reputation for reducers. FAQ 1. who are we?We are dependent in ZHangZhoug, China, start off from 2571,market to Eastern Asia(55.00%),North The us(5.00%),Jap Europe(5.00%),South Asia(5.00%). There are whole about 11-fifty men and women in our workplace.2. how can we assure good quality?Always a pre-creation sample ahead of mass productionAlways ultimate Inspection before shipment3.what can you acquire from us?speed reducer,Gearbox,Electric powered motor,Gearmotor,Couplings4. why ought to you buy from us not from other suppliers?We have some outstanding salesman ( with much more than 10 years epxort expertise)5. what solutions can we offer?Accepted Shipping Conditions: FOB,CFR,CIF,EXW,Specific Delivery;Accepted Payment Currency:USD,EUR,CNYAccepted Payment Kind: L/C,D/P D/A,MoneyGram,PayPal,Western Union,CashLanguage Spoken:English,Chinese,Spanish,Arabic,Russian Semi-Computerized PET Bottle Blowing Device Bottle Generating Equipment Bottle Moulding MachinePET Bottle Generating Device is appropriate for producing PET plastic containers and bottles in all styles. Title goes here.Semi-Automated PET Bottle Blowing Device Bottle Producing Device Bottle Moulding MachinePET Bottle Making Device is suitable for generating PET plastic containers and bottles in all styles.

The Parts of a Gearbox

There are many parts of a Gearbox, and this article will help you understand its functions and components. Learn about its maintenance and proper care, and you’ll be on your way to repairing your car. The complexity of a Gearbox also makes it easy to make mistakes. Learn about its functions and components so that you’ll be able to make the best choices possible. Read on to learn more. Then, get your car ready for winter!

Components

Gearboxes are fully integrated mechanical components that consist of a series of gears. They also contain shafts, bearings, and a flange to mount a motor. The terms gearhead and gearbox are not often used interchangeably in the motion industry, but they are often synonymous. Gearheads are open gearing assemblies that are installed in a machine frame. Some newer designs, such as battery-powered mobile units, require tighter integration.

The power losses in a gearbox can be divided into no-load and load-dependent losses. The no-load losses originate in the gear pair and the bearings and are proportional to the ratio of shaft speed and torque. The latter is a function of the coefficient of friction and speed. The no-load losses are the most serious, since they represent the largest proportion of the total loss. This is because they increase with speed.

Temperature measurement is another important preventive maintenance practice. The heat generated by the gearbox can damage components. High-temperature oil degrades quickly at high temperatures, which is why the sump oil temperature should be monitored periodically. The maximum temperature for R&O mineral oils is 93degC. However, if the sump oil temperature is more than 200degF, it can cause seal damage, gear and bearing wear, and premature failure of the gearbox.

Regardless of its size, the gearbox is a crucial part of a car’s drivetrain. Whether the car is a sports car, a luxury car, or a farm tractor, the gearbox is an essential component of the vehicle. There are two main types of gearbox: standard and precision. Each has its own advantages and disadvantages. The most important consideration when selecting a gearbox is the torque output.

The main shaft and the clutch shaft are the two major components of a gearbox. The main shaft runs at engine speed and the countershaft may be at a lower speed. In addition to the main shaft, the clutch shaft has a bearing. The gear ratio determines the amount of torque that can be transferred between the countershaft and the main shaft. The drive shaft also has another name: the propeller shaft.

The gears, shafts, and hub/shaft connection are designed according to endurance design standards. Depending on the application, each component must be able to withstand the normal stresses that the system will experience. Oftentimes, the minimum speed range is ten to twenty m/s. However, this range can differ between different transmissions. Generally, the gears and shafts in a gearbox should have an endurance limit that is less than that limit.

The bearings in a gearbox are considered wear parts. While they should be replaced when they wear down, they can be kept in service much longer than their intended L10 life. Using predictive maintenance, manufacturers can determine when to replace the bearing before it damages the gears and other components. For a gearbox to function properly, it must have all the components listed above. And the clutch, which enables the transmission of torque, is considered the most important component.

Functions

A gearbox is a fully integrated mechanical component that consists of mating gears. It is enclosed in a housing that houses the shafts, bearings, and flange for motor mounting. The purpose of a gearbox is to increase torque and change the speed of an engine by connecting the two rotating shafts together. A gearbox is generally made up of multiple gears that are linked together using couplings, belts, chains, or hollow shaft connections. When power and torque are held constant, speed and torque are inversely proportional. The speed of a gearbox is determined by the ratio of the gears that are engaged to transmit power.

The gear ratios in a gearbox are the number of steps a motor can take to convert torque into horsepower. The amount of torque required at the wheels depends on the operating conditions. A vehicle needs more torque than its peak torque when it is moving from a standstill. Therefore, the first gear ratio is used to increase torque and move the vehicle forward. To move up a gradient, more torque is required. To maintain momentum, the intermediate gear ratio is used.

As metal-to-metal contact is a common cause of gearbox failure, it is essential to monitor the condition of these components closely. The main focus of the proactive series of tests is abnormal wear and contamination, while the preventative tests focus on oil condition and additive depletion. The AN and ferrous density tests are exceptions to this rule, but they are used more for detecting abnormal additive depletion. In addition, lubrication is critical to the efficiency of gearboxes.

Maintenance

Daily maintenance is a critical aspect of the life cycle of a gearbox. During maintenance, you must inspect all gearbox connection parts. Any loose or damaged connection part should be tightened immediately. Oil can be tested using an infrared thermometer and particle counters, spectrometric analysis, or ferrography. You should check for excessive wear and tear, cracks, and oil leaks. If any of these components fail, you should replace them as soon as possible.

Proper analysis of failure patterns is a necessary part of any preventative maintenance program. This analysis will help identify the root cause of gearbox failures, as well as plan for future preventative maintenance. By properly planning preventative maintenance, you can avoid the expense and inconvenience of repairing or replacing a gearbox prematurely. You can even outsource gearbox maintenance to a company whose experts are knowledgeable in this field. The results of the analysis will help you create a more effective preventative maintenance program.

It is important to check the condition of the gearbox oil periodically. The oil should be changed according to its temperature and the hours of operation. The temperature is a significant determinant of the frequency of oil changes. Higher temperatures require more frequent changes, and the level of protection from moisture and water reduces by 75%. At elevated temperatures, the oil’s molecular structure breaks down more quickly, inhibiting the formation of a protective film.

Fortunately, the gear industry has developed innovative technologies and services that can help plant operators reduce their downtime and ensure optimal performance from their industrial gears. Here are 10 steps to ensure that your gearbox continues to serve its purpose. When you are preparing for maintenance, always keep in mind the following tips:

Regular vibration analysis is a vital part of gearbox maintenance. Increased vibration signals impending problems. Visually inspect the internal gears for signs of spiraling and pitting. You can use engineers’ blue to check the contact pattern of gear teeth. If there is a misalignment, bearings or housings are worn and need replacement. Also make sure the breathers remain clean. In dirty applications, this is more difficult to do.

Proper lubrication is another key factor in the life of gearboxes. Proper lubrication prevents failure. The oil must be free of foreign materials and have the proper amount of flow. Proper lubricant selection depends on the type of gear, reduction ratio, and input power. In addition to oil level, the lubricant must be regulated for the size and shape of gears. If not, the lubricant should be changed.

Lack of proper lubrication reduces the strength of other gears. Improper maintenance reduces the life of the transmission. Whether the transmission is overloaded or undersized, excessive vibration can damage the gear. If it is not properly lubricated, it can be damaged beyond repair. Then, the need for replacement gears may arise. However, it is not a time to waste a lot of money and time on repairs.

editor by czh

China supplier Helical worm reducer S Series worm helical speed geared reducer gearbox with motor 22KW replaced SEW with Hot selling

Product Description

| Model Variety | S collection Worm gear reducer | Construction Sort | S SA SAF SAT SAZ |

| Assembly Technique | one-six | Input energy | .eighteen-22W |

| Enamelled Wire: | 100% Copper Wire | Reducer body | Metal |

| Ratio | 10.27-230.forty eight | Manufacturer | FOX MOTOR |

When looking at a reducer vs a gearbox, usually the only variation is terminology. This is due to the fact all reducers are gearboxes. Nevertheless, not all gearboxes are retarders. This may seem complex, but it really is in fact very easy. A reducer is a equipment established in between the motor and the equipment. The function of the reducer is to decrease the rotational speed transferred in between these two endpoints. The reducer amplifies and multiplies the torque (input) made by the motor. 2nd, a reducer, as the identify suggests, reduces the velocity of the input (output in rpm) so that the output is the correct pace. The phrase “gearbox” is just a generic time period employed for the equipment teach amongst the motor and the equipment. As a result, all reducers are gearboxes. However, not all gearboxes reduce input speed. Even though uncommon, gearboxes can really increase enter speeds. By significantly the most common sort of gearbox is a retarder, but it would be incorrect to say that all gearboxes are retarders.

These compact, lightweight, minimal backlash inline equipment reducers ended up initially created for encoder apps. They are also ideal for numerous other travel programs. Encoder equipment reducers have a extremely reduced instant of inertia at the shaft input and are rated for input speeds up to 3000 rpm. Two body measurements are accessible with gear ratios from 4.96:1 to 3600:1. Our encoder gearbox sync pads are obtainable from stock.

China manufacturer S Series Hollow Shaft Helical Worm Reduction Reverse Gearbox near me shop

Solution Description

| Type: | S series Helical Worm Equipment Motors |

| Design: | S37-S97 |

| Brand identify: | YBANG |

| Shade: | Blue/Grey or on request |

| Material: | HT250 |

| Input electrical power: | .twelve-22kw |

| Output torque: | 11-4900N.m |

| Output pace: | .twelve-397rpm |

| Bearing: | C&U Bearing,NSK,SKF or on request |

| Seal: | SKF,CTY,CFW or on request |

| Origin: | ZHangZhoug, China |

| Warranty: | 1 yr |

Characteristics of goods

one. Hugely Standard Modular Designed: The items are easily linked with and driven by various varieties of motors and numerous input electricity. The identical kind geared motor can be tailored to optioned powers of motors. It is for that reason straightforward to understand various remedy for assorted requirements.

two. Ratio: Featured several closely divided ratios and extensive assortment of them. Extremely large final ratios can be received by way of blended unites to achieve extremely low output speeds.

three. Mounting Arrangement: No rigorous limitation to the mounting arrangement.

4. Substantial Strength, Compact Dimension: Housings are made of substantial power solid iron. Gears and shaft gears are completed with gas carburizing approach and exact grounding to sequentially get large loading potential of for each specific volume.

five. Prolonged Provider Lifestyle: Under the situation of precisely selecting sort dimensions and the standard maintenance and use, primary components (assume people easily-disabled components) can last as prolonged as up to a lot more than twenty five,000 hrs. Simply-disabled parts include lubricating oil, oil seals, and bearings.

6. Lower Noise: All crucial factors are completed by exactly machining, exact assembly, and lastly analyzed, and as a result, pretty minimal sounds is reached.

7. Large Effectiveness: The performance of gear unit can achieve 95%, The performance of worm gear unit can achieve 89%.

8. Big radial loading ability.

nine. Axial load capacity of up to 5% of radial load.

(1) With excellent top quality and Reasonable value

(2) Promise to shipping on time

(3) Secure, trustworthy, economical and sturdy

(4) Secure transmission, peaceful operation

(5) Substantial warmth-radiating effectiveness, large carrying potential

(6) Each solution must be examined prior to sending

Gear reducers are also referred to as reducers. Mechanical equipment, by possibly of these two names, are made to reduce the electricity transferred amongst the motor and the equipment between the rotational speeds (revolutions per moment). The reducer efficiently decreases the rotational velocity produced by the motor, thereby controlling the pace at which the device runs and rising the torque developed by the motor. Multiplying the torque made by the motor increases the machine’s available electrical power – a approach recognized as “mechanical dominance”. In a bigger context, gear reducers are generally instruments employed to increase the performance of equipment procedure.

Underneath is a checklist of our currently available industrial gearboxes. If you can not find what you are hunting for, make sure you speak to the manufacturing unit for much more choices. At EP, we are continuously building new products and retrofitting old types to meet up with consumer specifications.

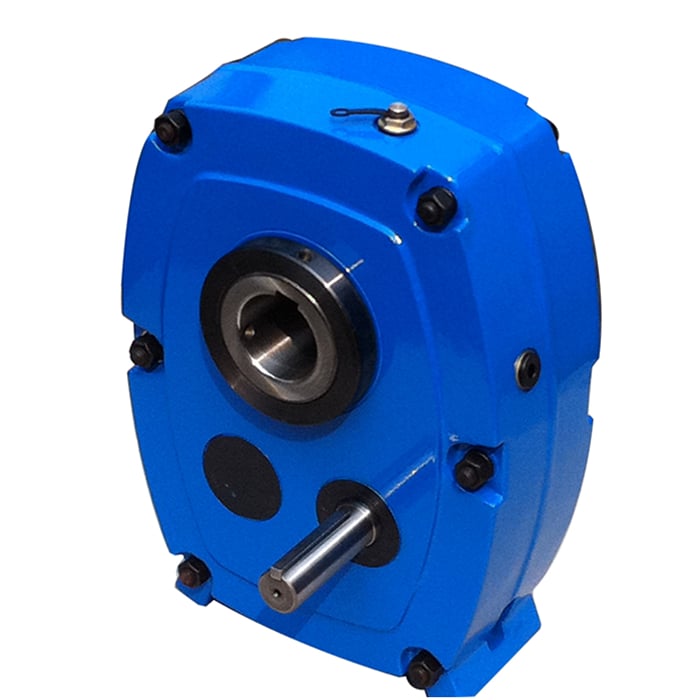

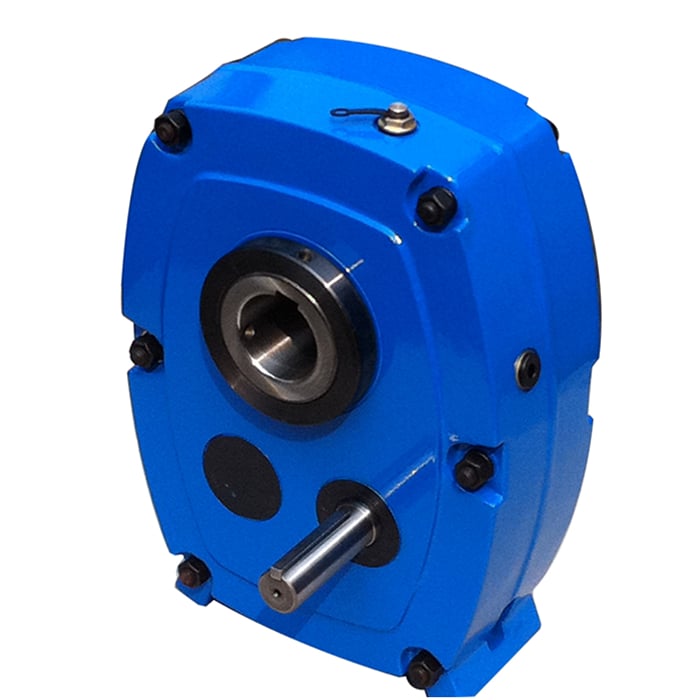

Best China manufacturer & factory SMR in Oklahoma City United States Shaft Mounted helical speed reducer worm gearbox 40 bevel gear box shaft drive unit txt shaft mounted gear speed reducer With high quality best price

Our solution range also covers locking assemblies (clamping elements/locking unit), taper bushes, QD bushes, bolt-on hubs, pto shaft, agricultural gearboxes,torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, universal joint, rod finishes and yokes.

Overview

Quick Specifics

- Applicable Industries:

-

Developing Material Stores, Manufacturing Plant, Equipment Restore Stores, txt shaft mounted gear pace reducer

Our merchandise are selling nicely in Chinese markets and some goods sold in international markets are effectively gained by Chinese and overseas consumers at property and overseas.

- Gearing Arrangement:

-

Helical

- Output Torque:

-

max 8000NM

- Enter Pace:

-

1440

- Output Pace:

-

seventy two, a hundred and ten, 288

- Spot of Origin:Zhejiang, China

- Manufacturer Name:

-

OEM

- Product Amount:

-

SMR

- Rated Electrical power:

-

two.68~134.2

- color of Shaft Mounted pace reducer:

-

environmentally friendly blue gray

Supply Potential

- Supply Potential:

- 5000 Piece/Parts per Thirty day period

Packaging & Shipping and delivery

- Packaging Specifics

- common export packing and wood pallets packing

- Port

- Shanghai or Ningbo

-

Lead Time

: -

Amount(Parts) EPG aims at actively playing a major part in a marketplace which retains creating new competition approaches with regard to high quality, financial system and existence. This aim is to be reached by indicates of the joint assist coming from all the company’s departments (Creation dept., Technical dept. and Product sales dept.) and a hugely expert around the world distribution community.

one – 5000 In our sales plan we supply standard and extensive-angle PTO generate shafts. Regarding the customers’ wants there are various measurements, lengths and protection aspects (clutches) available.

>5000 Est. Time(times) thirty To be negotiated

Online Customization

Solution Description

Solution Description

SMR Metric Sequence

Sizae: B-J

Ratio: 5:1, 13:1, twenty:1

Greatest Output Torque: 8000 Nm

SMR Shafted mounted equipment velocity reducer:

1) Shafted mounted gear unit for conveyer systems

2) All gears are warmth handled and fixed to achieve minimal noise and high output

3) Mounting proportions are interchangeable with Fene

Item Paramenters

Product Paramenters

Relevant Merchandise

Associated Products

Product packaging

Product packaging

FAQ

FAQ

Q: Are you buying and selling business or company ?

A: HZPT group is made up in 3 factories and 2 abroad sales cooperations.we are making vacuum pumps,air compressors and gearboxes.

Q: How lengthy is your shipping and delivery time ? What is your phrases of payment ?

A: Typically it is thirty-forty five times. The time may range depending on the item and the amount of customization. For regular goods,

the payment is: thirty% T/T in advance ,harmony before shippment.,for tailored merchandise,fifty% downpayment is requested generally.

Q: What is the precise MOQ or price for your solution ?

A: As an OEM business, we can offer and adapt our items to a vast range of wants.Thus, MOQ and price may possibly tremendously range with depth dimension, substance and further specificationswhen you place orders,satisfaction get in touch with us in progress to communicate all specifics

Dls Helical Worm Gear Reducer

S collection Helical Worm Reducer

one. Simple Details:

| Gear Material | Low carbon higher alloy metal |

| Heat treatment | Carburising, Quenching, Gear Grinding |

| CZPT | CLP (CC) VG220 |

| Ambient Temperature | -10ºC~40ºC |

two. Package deal and Supply:

All Types: CZPT Package

Supply: About two months right after receiving the advanced payment.

3. Characteristics and Benefits

one) Undertake “module mixture” design.It can be changed out of tens of millions of varieties of “module” assembled by the reducer, any consumer of any demand from customers, can be a short time to obtain the optimum fulfillment.

2) Two helical gearboxes combined with a motor (a multistage reducer) can accomplish extremely minimal output speed

3) Large transmission precision, particularly appropriate for repeated starting instances, can be linked to all varieties of reducer and configuration of different kinds of motor drive

4) More ratios satisfy the want of exact output speed.

5) Gearmotor can be provided for either horizontal or vertical set up in 6 angle.

6) Undertake two or three equipment reduction, by the motor drive large – velocity stage transmission electrical power.The input middle line is parallel to the output heart line

7) This series of reducer can be outfitted with a variety of types of motors, forming the electromechanical integration, totally make certain the high quality attributes of the solution

eight) Improved electricity ability,decrease noise and higher efficiency by grinding and modifying gears.

four. Product Kind

5. Torque arm and position

DLSAT, DLSHT gear models and gearmotors can be mounted with torque arm. The positions designation as adhering to:

six. Placement of Output shaft and output flange

seven. Mounting Position

DONLY differentiates amongst 6 mounting positions M1…M6 for equipment models and gearmotors. The subsequent determine demonstrates the position of the equipment device in mounting positions M1-M6.

8. Position of terminal box and cable entry

The situation of the motor terminal box has so far been specified indicated with L(left), R(proper), T(top) or B(base) as considered on to the output shaft.

The placement of the cable entry can be selected as nicely. The positions are equal to CZPT position, “one”, “2”or “3”.

9. Motor Adaptor Selection

10. Deal Pictures

eleven. FAQ

1) What varieties of gearbox can you generate for us.

A: Major merchandise of our business: Modular Gearmotor R,F,K,S. Substantial CZPT Modular Gearbox H,B,P,HK. A few-Stage Asynronous Motor. Customerized Gearbox.

two) Can you make as per custom made drawing?

A: Indeed, we supply CZPT service for clients.

3) What is your terms of payment?

A: 30% sophisticated payment by T/T after signing the deal. 70% just before shipping and delivery.