Product Description

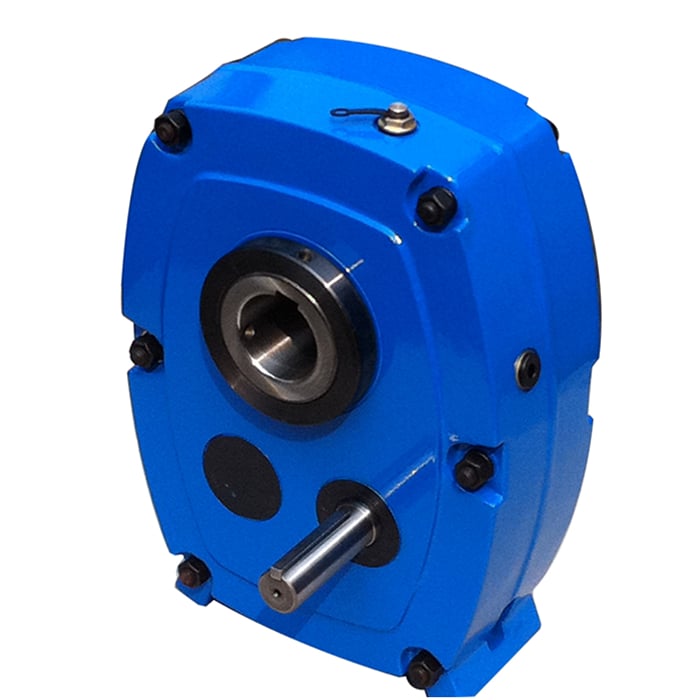

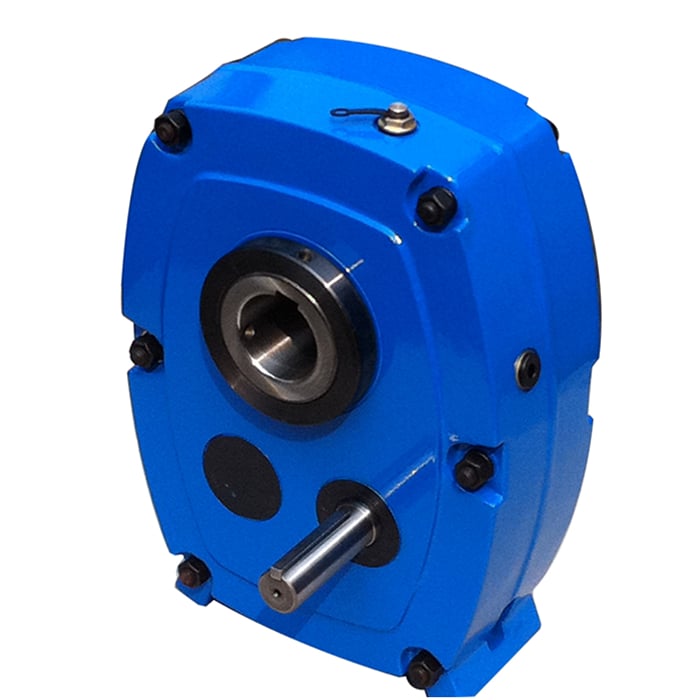

Worm Gear Speed Reducer Unit

|

Input Configurations |

Double or single input shaft (NRV) |

|

PAM / IEC motor input shaft with circle or square flange (NMRV) |

|

|

Output Configurations

|

Double or single output shaft |

|

Output flange |

Main Feature

The gearbox can rotate in both directions operate and contains 1 oil filling at delivery. you will benefit from its high quality and a short delivery time.

Specification

|

Model |

Motor Input Flange (circle) |

Transmission Ratio |

Power (kw) |

Ratio (i) |

Nominal Torque (Nm) |

|||||||||||||||

|

PAM / IEC |

Internal Dia. |

Dis. Between Diagonal Screw Holes |

External Dia. |

Width of Key Slot |

5 |

7.5 |

10 |

15 |

20 |

25 |

30 |

40 |

50 |

60 |

80 |

100 |

||||

|

N |

M |

P |

E |

Diamter of Input Shaft |

||||||||||||||||

|

NMRV25 |

56B14 |

50 |

65 |

80 |

3 |

9 |

– |

9 |

– |

0.06 |

7.5-60 |

2.6-14 |

||||||||

|

NMRV30 |

63B5 |

95 |

115 |

140 |

4 |

11 |

– |

0.06-0.18 |

7.5-80 |

2.6-14 |

||||||||||

|

63B14 |

60 |

75 |

90 |

|||||||||||||||||

|

56B5 |

80 |

100 |

120 |

3 |

9 |

– |

||||||||||||||

|

56B14 |

50 |

65 |

80 |

|||||||||||||||||

|

NMRV40 |

71B5 |

110 |

130 |

160 |

5 |

14 |

– |

0.09-0.37 |

7.5-100 |

11-53 |

||||||||||

|

71B14 |

70 |

85 |

105 |

|||||||||||||||||

|

63B5 |

95 |

115 |

140 |

4 |

11 |

|||||||||||||||

|

63B14 |

60 |

75 |

90 |

|||||||||||||||||

|

56B5 |

80 |

100 |

120 |

3 |

– |

9 |

||||||||||||||

|

NMRV50 |

80B5 |

130 |

165 |

200 |

6 |

19 |

– |

0.12-0.75 |

7.5-100 |

21-89 |

||||||||||

|

80B14 |

80 |

100 |

120 |

|||||||||||||||||

|

71B5 |

110 |

130 |

160 |

5 |

14 |

– |

||||||||||||||

|

71B14 |

70 |

85 |

105 |

|||||||||||||||||

|

63B5 |

95 |

115 |

140 |

4 |

– |

11 |

||||||||||||||

|

NMRV63 |

90B5 |

130 |

165 |

200 |

8 |

24 |

– |

0.25-1.5 |

7.5-100 |

56-166 |

||||||||||

|

90B14 |

95 |

115 |

140 |

|||||||||||||||||

|

80B5 |

130 |

165 |

200 |

6 |

19 |

– |

||||||||||||||

|

80B14 |

80 |

100 |

120 |

|||||||||||||||||

|

71B5 |

110 |

130 |

160 |

5 |

– |

14 |

||||||||||||||

|

71B14 |

70 |

85 |

105 |

|||||||||||||||||

|

NMRV75 |

100/112B5 |

180 |

215 |

250 |

8 |

– |

28 |

– |

0.55-4 |

7.5-100 |

90-269 |

|||||||||

|

100/112B14 |

110 |

130 |

160 |

|||||||||||||||||

|

90B5 |

130 |

165 |

200 |

8 |

24 |

– |

||||||||||||||

|

90B14 |

95 |

115 |

140 |

|||||||||||||||||

|

80B5 |

130 |

165 |

200 |

6 |

– |

19 |

||||||||||||||

|

80B14 |

80 |

100 |

120 |

|||||||||||||||||

|

71B5 |

110 |

130 |

160 |

– |

– |

14 |

||||||||||||||

|

NMRV90 |

100/112B5 |

180 |

215 |

250 |

8 |

– |

28 |

– |

0.55-4 |

7.5-100 |

101-458 |

|||||||||

|

100/112B14 |

110 |

130 |

160 |

|||||||||||||||||

|

90B5 |

130 |

165 |

200 |

8 |

24 |

– |

||||||||||||||

|

90B14 |

95 |

115 |

140 |

|||||||||||||||||

|

80B5 |

130 |

165 |

200 |

6 |

– |

19 |

||||||||||||||

|

80B14 |

80 |

100 |

120 |

|||||||||||||||||

|

NMRV110 |

132B5 |

230 |

265 |

300 |

10 |

– |

38 |

– |

1.1-7.5 |

7.5-100 |

242-660 |

|||||||||

|

132B14 |

130 |

165 |

200 |

– |

||||||||||||||||

|

100/112B5 |

180 |

215 |

250 |

8 |

28 |

– |

||||||||||||||

|

90B5 |

130 |

165 |

200 |

– |

24 |

|||||||||||||||

|

90B14 |

95 |

115 |

140 |

– |

||||||||||||||||

|

80B5 |

130 |

165 |

200 |

– |

19 |

|||||||||||||||

|

NMRV130 |

132B5 |

230 |

265 |

300 |

10 |

– |

38 |

– |

2.2-7.5 |

7.5-100 |

333-1596 |

|||||||||

|

132B14 |

130 |

165 |

200 |

– |

||||||||||||||||

|

100/112B5 |

180 |

215 |

250 |

8 |

– |

28 |

||||||||||||||

|

90B5 |

130 |

165 |

200 |

– |

– |

24 |

||||||||||||||

|

90B14 |

95 |

115 |

140 |

|||||||||||||||||

|

NMRV150 |

160B5 |

250 |

300 |

350 |

12 |

– |

42 |

– |

2.2-15 |

7.5-100 |

570-1760 |

|||||||||

|

132B5 |

230 |

265 |

300 |

10 |

– |

38 |

– |

|||||||||||||

|

132B14 |

130 |

165 |

200 |

– |

||||||||||||||||

|

100/112B5 |

180 |

215 |

250 |

8 |

– |

28 |

||||||||||||||

Company profile

Scenario

Packing

FAQ

Q1: I want to buy your products, how can I pay?

A: You can pay via T/T(30%+70%), L/C ,D/P etc.

Q2: How can you guarantee the quality?

A: One year’s warranty against B/L date. If you meet with quality problem, please send us pictures or video to check, we promise to send spare parts or new products to replace. Our guarantee not include inappropriate operation or wrong specification selection.

Q3: How we select models and specifications?

A: You can email us the series code (for example: RC series helical gearbox) as well as requirement details, such as motor power,output speed or ratio, service factor or your application…as much data as possible. If you can supply some pictures or drawings,it is nice.

Q4: If we don’t find what we want on your website, what should we do?

A: We offer 3 options:

1, You can email us the pictures, drawings or descriptions details. We will try to design your products on the basis of our

standard models.

2, Our R&D department is professional for OEM/ODM products by drawing/samples, you can send us samples, we do customized design for your bulk purchasing.

3, We can develop new products if they have good market. We have already developed many items for special using successful, such as special gearbox for agitator, cement conveyor, shoes machines and so on.

Q5: Can we buy 1 pc of each item for quality testing?

A: Yes, we are glad to accept trial order for quality testing.

Q6: How about your product delivery time?

A: Normally for 20’container, it takes 25-30 workdays for RV series worm gearbox, 35-40 workdays for helical gearmotors.

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | B3,B6,B7,B8,V5,V6 |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

What is a Worm Gearbox and How Does It Work?

A worm gearbox, also known as a worm gear reducer, is a mechanical device used to transmit rotational motion an

How to Install and Align a Worm Reducer Properly

Proper installation and alignment of a worm reducer are crucial for ensuring optimal performance and longevity. Follow these steps to install and align a worm reducer:

- Preparation: Gather all the necessary tools, equipment, and safety gear before starting the installation process.

- Positioning: Place the worm reducer in the desired location, ensuring that it is securely mounted to a stable surface. Use appropriate fasteners and mounting brackets as needed.

- Shaft Alignment: Check the alignment of the input and output shafts. Use precision measurement tools to ensure that the shafts are parallel and in line with each other.

- Base Plate Alignment: Align the base plate of the reducer with the foundation or mounting surface. Ensure that the base plate is level and properly aligned before securing it in place.

- Bolt Tightening: Gradually and evenly tighten the mounting bolts to the manufacturer’s specifications. This helps ensure proper contact between the reducer and the mounting surface.

- Check for Clearance: Verify that there is enough clearance for any rotating components or parts that may move during operation. Avoid any interference that could cause damage or performance issues.

- Lubrication: Apply the recommended lubricant to the worm reducer according to the manufacturer’s guidelines. Proper lubrication is essential for smooth operation and reducing friction.

- Alignment Testing: After installation, run the worm reducer briefly without a load to check for any unusual noises, vibrations, or misalignment issues.

- Load Testing: Gradually introduce the intended load to the worm reducer and monitor its performance. Ensure that the reducer operates smoothly and efficiently under the load conditions.

It’s important to refer to the manufacturer’s installation guidelines and specifications for your specific worm reducer model. Proper installation and alignment will contribute to the gearbox’s reliability, efficiency, and overall functionality.

d torque between non-parallel shafts. It consists of a worm screw and a worm wheel, both of which have helical teeth. The worm screw resembles a threaded cylinder, while the worm wheel is a gear with teeth that mesh with the worm screw.

The working principle of a worm gearbox involves the interaction between the worm screw and the worm wheel. When the worm screw is rotated, its helical teeth engage with the teeth of the worm wheel. As the worm screw rotates, it translates the rotational motion into a perpendicular motion, causing the worm wheel to rotate. This perpendicular motion allows the worm gearbox to achieve a high gear reduction ratio, making it suitable for applications that require significant speed reduction.

One of the key features of a worm gearbox is its ability to provide a high gear reduction ratio in a compact design. However, due to the sliding nature of the meshing teeth, worm gearboxes may exhibit higher friction and lower efficiency compared to other types of gearboxes. Therefore, they are often used in applications where efficiency is not the primary concern but where high torque and speed reduction are essential, such as conveyor systems, elevators, automotive steering systems, and certain industrial machinery.

editor by

Worm Gearboxes in Conveyor Systems: Benefits and Considerations

Worm gearboxes play a crucial role in conveyor systems, offering several benefits and considerations for their effective integration:

- Space Efficiency: Worm gearboxes have a compact design, making them suitable for applications with limited space, such as conveyor systems.

- High Reduction Ratios: Worm gearboxes can achieve high reduction ratios in a single stage, allowing for slower conveyor speeds without sacrificing torque.

- Self-Locking: Worm gearboxes have inherent self-locking properties, preventing the conveyor from moving when the motor is not actively driving it.

- Directional Control: Worm gearboxes facilitate directional control, enabling the conveyor to move forward or reverse as needed.

- Low Noise: Worm gearboxes often produce lower noise levels compared to other gearbox types, contributing to quieter conveyor operation.

However, there are also considerations to keep in mind when using worm gearboxes in conveyor systems:

- Efficiency: Worm gearboxes may have lower mechanical efficiency compared to some other gearbox types, leading to energy losses.

- Heat Generation: Worm gearboxes can generate more heat due to sliding contact between the worm and gear, necessitating proper cooling mechanisms.

- Lubrication: Proper lubrication is critical to prevent wear and ensure efficient operation. Regular maintenance is required to monitor lubrication levels.

- Load and Speed: Worm gearboxes are well-suited for applications with high torque and low to moderate speed requirements. They may not be optimal for high-speed conveyors.

Before integrating a worm gearbox into a conveyor system, it’s important to carefully consider the specific requirements of the application, including load, speed, space constraints, and efficiency needs. Consulting with gearbox experts and manufacturers can help ensure the right choice for the conveyor’s performance and longevity.

CX 2023-08-22

China Good quality Helical Gear Reducer High Speed Planetary Reduction Gearbox for Industrial Using with Hot selling

Product Description

Planetary Series High Electricity Equipment Box

Housing is manufactured of cast iron,which enhance its rigidity and anti-vibration.

Sun and plant gears are processed by cementite and hardening,gears are procedures by grinding,which increase the performance and life time of the gearbox.

Input manner:coaxial input,helical equipment enter,bevel-helical gear enter.

Output mode:inside involute spline,hollow shaft with shrink disk,exterior involute spline,reliable shaft with flat important.

Mounting manner:Horizonal vertical,torque-arm.

P series sizes 9~34 transmission phase:2~3 ratio:25~4000

Ratio will be more substantial in combination with H,R,K sequence.

RFQ

Q:Are you investing company or company?

A: We are maker with more than twenty years’ encounter.

Q: How long is your shipping time?

A: Usually it is in 10 times if the items are in inventory, for merchandise made as for every purchase, it is in 35 days soon after affirmation of get.

Q: How prolonged must I hold out for the opinions right after I send the enquiry?

A: Normally within twelve several hours.

Q: What info should I give you to confirm the item?

A: Product/Dimensions, Transmission Ratio, Velocity, Shaft instructions & Buy amount and many others.

Q: Hong long is your product guarantee?

A: We provide 12 months warranty from departure day of the goods.

Q: What is your payment phrases? T/T a hundred% in CZPT for quantity much less than USD10000.-, thirty% T/T in CZPT , harmony prior to cargo for quantity over USD10000.

If you have any other questions, make sure you come to feel free to contact us beneath:

HOW TO Get in touch with US?

Deliver your Inquiry Specifics in the Beneath, click on “Send” Now!

Gearboxes go by numerous different names, like equipment drives, pace reducers, equipment reducers, velocity reducers, and gear motors. All conditions are employed interchangeably when referring to inline gear reducers. Our inventory consists of a extensive selection of equipment reducers for higher speed, substantial precision apps with enter speeds up to 4000 RPM.

Gearboxes can be utilised in a variety of fields of comprehensive processing, agriculture, chemical processing, oil and gasoline, power transmission and distribution methods, logistics, warehousing and other industries. Equipment reducers are usually utilized the place greater torque and/or reduced rotational speeds are essential, or if power needs to be transmitted at alternating angles, such as in correct-angle motors. It can also adjust the path of rotation, as nicely as clockwise and counterclockwise. EP provides a comprehensive range of gear reducers with right angle worms and substantial effectiveness possibilities. Electrical Equipment Aluminum items are a lightweight and sturdy different to present day forged iron and metal designs and can be stocked or custom produced to your exact specifications. EP gearboxes are light-weight and durable, aluminum worm gearboxes are developed for tight spaces, like challenging-to-put in OEM patterns as nicely as mobile equipment. Eccentric reducers are available as compact aluminum or forged iron inline reducers with seal life rankings from 15HP (aluminum) to 40HP (cast iron). In addition to our common and modified standard items, our engineers will operate with you to design and develop custom made solutions for numerous generate systems to go well with your application wants.

China high quality CZPT Wpx/Wpo 40/50/60/70/80/100 Ratio Worm Gear Speed Reducer Gearbox with high quality

Solution Description

Solution Description

| Product No. | Wpa/Wps/Wpo/Wpx/Wpz/Wpw/Wpz |

| Ratio | 1:ten,fifteen,twenty,twenty five,thirty,40,50,60 |

| Colour | inexperienced |

| Material |

Housing: Die-Solid Iron solid |

| Worm Equipment-Copper-ten-3# | |

| Worm-20CrMn Ti with carburizing and quenching, surface harness is 56-62HRC | |

| Shaft-chromium Steel-45# | |

| Usages | Industrial Device: Meals Stuff, Ceramics, Chemical, Packing, Dyeing,Wood doing work, Glass. |

Company Profile

In 2571, HangZhou CZPT Machinery Co.,ltd was established by Ms. Iris and her 2 associates(Mr. Tian and Mr. Yang) in HangZhou metropolis(ZHangZhoug province, China), all 3 Founders are engineers who have far more than averaged 30 many years of expertise. Then due to the fact the requirements of enterprise expansion, in 2014, it moved to the existing Xihu (West Lake) Dis. Industrial Zone (HangZhou metropolis, ZHangZhoug province, China).

By way of our effectively-identified model ND, CZPT Machinery delivers agricultural solutions to agriculture equipment producer and distributors around the world by way of a total line of spiral bevel gearboxes, straight bevel gearboxes, spur gearboxes, generate shafts, sheet steel, hydraulic cylinder, motors, tyre, worm gearboxes, worm operators etc. Merchandise can be tailored as ask for.

We, CZPT equipment proven a complete top quality administration program and sales support network to provide customers with high-quality merchandise and satisfactory service. Our goods are sold in forty provinces and municipalities in China and 36 countries and areas in the world, our primary marketplace is the European industry.

Certifications

Our Manufacturing facility

Sample Room

Why decide on us?

1) Customization: With a sturdy R&D crew, and we can build products as required. It only will take up to 7 times for us to style a set of drawings. The manufacturing time for new products is normally 50 times or much less.

two) High quality: We have our possess comprehensive inspection and screening products, which can guarantee the good quality of the items.

three) Capability: Our once-a-year production ability is over five hundred,000 sets, also, we also acknowledge modest amount orders, to satisfy the demands of diverse customer’s purchase quantities.

four) Provider: We emphasis on giving large-top quality goods. Our merchandise are in line with intercontinental expectations and are primarily exported to Europe, Australia, and other international locations and regions.

5) Cargo: We are shut to HangZhou and ZheJiang ports, to supply the swiftest shipping service.

Packaging & Shipping

FAQ

Q: Are you a investing firm or manufacturer?

A: We’re manufacturing unit and providing gearbox ODM & OEM providers for the European marketplace for much more than ten a long time

Q: Do you supply samples? is it free of charge or extra?

A: Yes, we could provide the sample for free of charge demand but do not pay out the expense of freight.

Q: How extended is your delivery time? What is your phrases of payment?

A: Normally it is forty-forty five times. The time may differ depending on the product and the amount of customization.

For standard merchandise, the payment is: 30% T/T in advance,equilibrium just before cargo.

Q: What is the specific MOQ or price for your product?

A: As an OEM business, we can supply and adapt our items to a wide range of needs.

Thus, MOQ and price tag may possibly greatly differ with measurement, materials and additional specifications For instance, pricey items or standard items will generally have a reduced MOQ. You should get in touch with us with all appropriate specifics to get the most precise quotation.

If you have one more query, please truly feel free of charge to contact us.

These compact, light-weight, low backlash inline gear reducers were at first developed for encoder purposes. They are also ideal for numerous other travel programs. Encoder gear reducers have a very lower instant of inertia at the shaft input and are rated for enter speeds up to 3000 rpm. Two frame sizes are offered with gear ratios from 4.ninety six:1 to 3600:1. Our encoder gearbox sync pads are available from stock.

Under is a list of our currently accessible industrial gearboxes. If you cannot discover what you are hunting for, please speak to the manufacturing unit for more alternatives. At EP, we are continuously creating new goods and retrofitting old ones to fulfill customer needs.

China best RV Series Nmrv 025-125 Gearbox Aluminum Cast Iron Wheel Reduction Transmission Drive Speed Reducer Worm Gear Box with high quality

Merchandise Description

Rv Series Nmrv 571-one hundred twenty five gearbox Aluminum Cast Iron Wheel Reduction Transmission Push Speed Reducer Worm Equipment Box

Goods Attributes

1. Manufactured of large-top quality aluminum alloy,light-weight bodyweight and non-rusting

2. Big output torque

three. Sleek in managing and minimal in sounds,can function long time in dreadful problems.

4. Higher in radiating performance.

5. Excellent-searching in physical appearance,tough in service existence and small in quantity.

6. Suitable for omnibearing set up.

Features of Worm Reducer /Gearbox

one.Widespread mounting dimensions.

two.Aluminum and forged iron housing.

three.Worm and worm wheel transmission.

four.Compact framework and gentle-bodyweight.

5.Vast assortment of equipment.

Benefits of Worm Gearbox / Reducer

1.Unique housing style will distinguish you from other competition.

two.Multiple choice for oil seal.

3.The dimensions can be custom-made according to customer’s needs.

|

Model No |

NMRV571, NMRV030, NMRV040, NMRV050, NMRV063, NMRV075, NMRV090, NMRV110, NMRV130, NMRV150 |

|

Ratio |

five,7.5,10,fifteen,twenty,25,30,forty,fifty,sixty,80,one hundred |

|

Material |

Housing: Size 25-a hundred and ten Is Aluminum Alloy, Dimension one hundred ten-one hundred fifty Is Cast-Iron |

|

Worm Wheel: ZCuSn10Pb1 |

|

|

Worm:20Cr |

|

|

Pinion:Tin Bronze |

|

|

Output Shaft: Steel-45# |

|

|

Variety |

Worm Equipment Velocity Reducer / Gearbox / Reductor |

|

Colour |

Tailored Coloration |

|

Packing |

Carton, Honey Comb Carton, Wood Situation with Picket Pallet |

|

Use |

Industrial Machine, Foods Stuff, Ceramics, Chemical, Packing, Dyeing, Wooden Working, Glass, and so forth. |

|

Flange |

IEC common flange or custom-made dimensions |

|

Housing Content |

Aluminum&Forged iron |

|

Measurement |

11 measurements(WMRV25~WMRV185) |

|

Energy |

.06~22 KW |

|

Nominal torque |

≤2548 N.m |

|

Ratio |

5~one hundred |

Connected Products

Organization Details

The expression “gearbox” is utilized to refer to any unit that connects a motor to a equipment and is made up of a series of gears, also acknowledged as a equipment established. It receives the main input speed from the motor and alterations it to a various output velocity employing its gears. Various types and mixtures of gears serve certain reasons. The sorts of gears found in gearboxes include spur gears, bevel gears, helical gears, helical gears and worm gears. The performance efficiency of a gearbox is represented by the gearbox ratio, which is the ratio of the speed of the enter supply to the velocity of the output resource

Gearboxes go by several distinct names, like gear drives, speed reducers, equipment reducers, pace reducers, and equipment motors. All phrases are employed interchangeably when referring to inline gear reducers. Our inventory involves a extensive selection of gear reducers for substantial speed, substantial precision purposes with enter speeds up to 4000 RPM.

China manufacturer & factory supplier for K in Cabinda Angola series helical gear box hard tooth surface of helical gear speed reducer industry machines with gear motor 1.5KW With high quality best price & service

EP Group has improved its organization lines to contain Energy Transmission Units and Components, Automotive Components and Supplies Dealing with Techniques.The substantial specific CNC equipment, this kind of as Sluggish-feeding wire-cut equipment, jig grinding device and electric discharge equipment, ensures the top top quality precision of mould processing, with the substantial efficient and environmental protection acid rolling line currently being the biggest uncooked content changing gear in the subject in china The wildly use of automated milling device, large-speed automated feeding punch, high pace automatic rolling and assembling device assures the substantial top quality and performance of factors and chain creating.

Overview

Quick Particulars

- Relevant Industries:

-

Developing Materials Outlets, Manufacturing Plant, Machinery Fix Outlets, Farms, Power & Mining, Building performs

- Spot of Origin:Zhejiang, China

- Manufacturer Identify:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

800~100000N.m

- Input Speed:

-

1400rpm

- Output Speed:

-

fourteen-280rpm

- Ratio:

-

seven.5~one hundred

- Certification:

-

ISO9001-2008

- Mount Place:

-

Foot Mounted

- Bearing:

-

C&U,LYC

- Guarantee:

-

1 Yr

- Solution identify:

-

Equipment Box

- Coloration:

-

Blue

- Packing:

-

Wooden Box

Offer Potential

- Supply Potential:

- a thousand Unit/Units per Thirty day period

Packaging & Delivery

-

Cat 3 Point Hitch How do I operate the PTO on my tractor? Prior to working the PTO, you will need your tractor to attain the starting up RPM (revolutions for each moment). After the beginning RPM has been arrived at you can commence working the PTO.

- Packaging Details

- Wood containers , Cantons packed in 1 pallet

- Port

- Ningbo Port, Shanghai Port

-

Direct Time

: -

Amount(Packing containers) 1 – 1 >1 Est. Time(days) 15 To be negotiated

On the web Customization

K Collection Helical Bevel Reduction Gearbox

Features of goods

one. Highly Regular Modular Created: The merchandise are simply connected with and pushed by distinct kinds of motors and numerous input power. The same sort geared motor can be tailored to optioned powers of motors. It is therefore simple to comprehend different solution for diverse requirements.

two. RatiOUR Standard Segment: Software-Acceptable PRECISIONo: Highlighted many closely divided ratios and broad range of them. Quite huge ultimate ratios can be received by way of merged unites to reach really reduced output speeds.

3. Mounting Arrangement: No rigid limitation to the mounting arrangement.

four. Large Toughness, Compact Dimension: Housings are manufactured of high toughness solid iron. Gears and shaft gears are completed with gasoline carburizing procedure and exact grounding to sequentially get higher loading capacity of for each certThe company covering 88,000 sq. meters, has sophisticated products and powerful specialized power, these kinds of as the numerical handle machine equipment and machining centers, CAD/CAM program, industrial robotic and so on. ain quantity.

5. Long Provider Existence: Beneath the situation of correctly deciding on kind dimension and the regular servicing and use, principal components (expect people very easily-disabled areas) can previous as long as up to much more than 25,000 several hours. Easily-disabled elements contain lubricating oil, oil seals, and bearings.

6. Lower Sound: All key factors are completed by specifically machining, exact assembly, and finally analyzed, and therefore, fairly lower noise is attained.

7. High Efficiency: The efficiency of equipment unit can get to 95%, The effectiveness of worm gear device can reach 89%.

eight. Massive radial loading capability.

9. Axial load ability of up to 5% of radial load.

|

Product: |

K Sequence – Foot-mounted, solid shaft output |

|

Housing |

Cast Iron |

|

Input energy |

.twelve-200kw |

|

Output torque |

ten-61900N.m |

|

Output velocity |

.08-261rpm |

|

Bearing |

C&U Bearing,NSK,SKF or on request |

|

Ratio |

five.36~178.37 |

|

Installation Sort |

Foot, Flange, Shaft Mounted |

|

Seal |

SKF,CTY,CFW or on request |

|

Gears |

Helical-bevel Gears |

|

Enter Configurations |

Geared up with Electric Motors |

|

Relevant Motors |

One Stage AC Motor, Three Period AC Motor |

|

Output Configurations |

Strong Shaft Output |

|

nstallation |

Foot-mounted |

|

Lubrication |

Oil-bath and Splash Lubrication |

Installation Technique

For more models, remember to make contact with us!

Suggest Merchandise

Firm Data

Solution packaging

FAQ

Best China manufacturer & factory SMR in Oklahoma City United States Shaft Mounted helical speed reducer worm gearbox 40 bevel gear box shaft drive unit txt shaft mounted gear speed reducer With high quality best price

Our solution range also covers locking assemblies (clamping elements/locking unit), taper bushes, QD bushes, bolt-on hubs, pto shaft, agricultural gearboxes,torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, universal joint, rod finishes and yokes.

Overview

Quick Specifics

- Applicable Industries:

-

Developing Material Stores, Manufacturing Plant, Equipment Restore Stores, txt shaft mounted gear pace reducer

Our merchandise are selling nicely in Chinese markets and some goods sold in international markets are effectively gained by Chinese and overseas consumers at property and overseas.

- Gearing Arrangement:

-

Helical

- Output Torque:

-

max 8000NM

- Enter Pace:

-

1440

- Output Pace:

-

seventy two, a hundred and ten, 288

- Spot of Origin:Zhejiang, China

- Manufacturer Name:

-

OEM

- Product Amount:

-

SMR

- Rated Electrical power:

-

two.68~134.2

- color of Shaft Mounted pace reducer:

-

environmentally friendly blue gray

Supply Potential

- Supply Potential:

- 5000 Piece/Parts per Thirty day period

Packaging & Shipping and delivery

- Packaging Specifics

- common export packing and wood pallets packing

- Port

- Shanghai or Ningbo

-

Lead Time

: -

Amount(Parts) EPG aims at actively playing a major part in a marketplace which retains creating new competition approaches with regard to high quality, financial system and existence. This aim is to be reached by indicates of the joint assist coming from all the company’s departments (Creation dept., Technical dept. and Product sales dept.) and a hugely expert around the world distribution community.

one – 5000 In our sales plan we supply standard and extensive-angle PTO generate shafts. Regarding the customers’ wants there are various measurements, lengths and protection aspects (clutches) available.

>5000 Est. Time(times) thirty To be negotiated

Online Customization

Solution Description

Solution Description

SMR Metric Sequence

Sizae: B-J

Ratio: 5:1, 13:1, twenty:1

Greatest Output Torque: 8000 Nm

SMR Shafted mounted equipment velocity reducer:

1) Shafted mounted gear unit for conveyer systems

2) All gears are warmth handled and fixed to achieve minimal noise and high output

3) Mounting proportions are interchangeable with Fene

Item Paramenters

Product Paramenters

Relevant Merchandise

Associated Products

Product packaging

Product packaging

FAQ

FAQ

Q: Are you buying and selling business or company ?

A: HZPT group is made up in 3 factories and 2 abroad sales cooperations.we are making vacuum pumps,air compressors and gearboxes.

Q: How lengthy is your shipping and delivery time ? What is your phrases of payment ?

A: Typically it is thirty-forty five times. The time may range depending on the item and the amount of customization. For regular goods,

the payment is: thirty% T/T in advance ,harmony before shippment.,for tailored merchandise,fifty% downpayment is requested generally.

Q: What is the precise MOQ or price for your solution ?

A: As an OEM business, we can offer and adapt our items to a vast range of wants.Thus, MOQ and price may possibly tremendously range with depth dimension, substance and further specificationswhen you place orders,satisfaction get in touch with us in progress to communicate all specifics