Product Description

PROFESSIONAL MANUFACTURE

— SINCE 1995

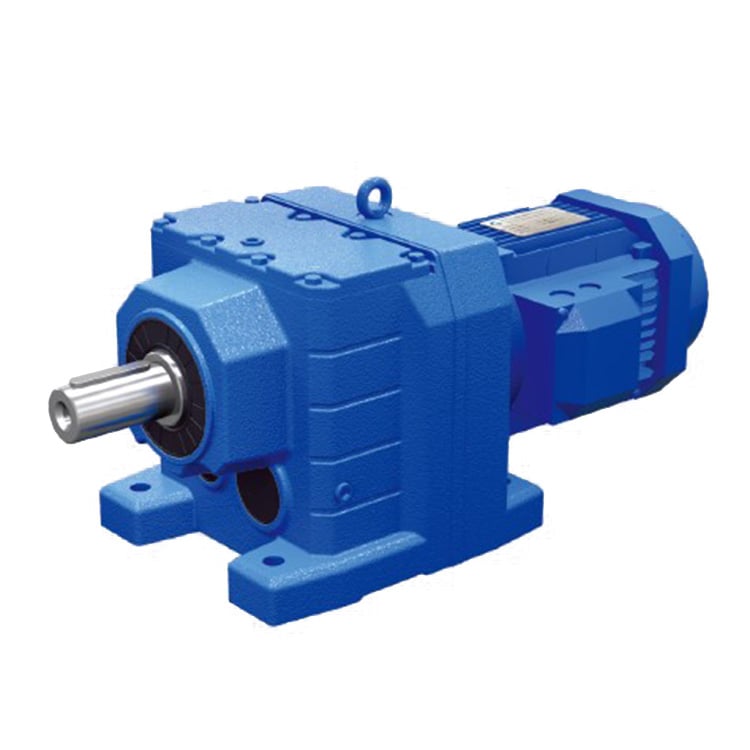

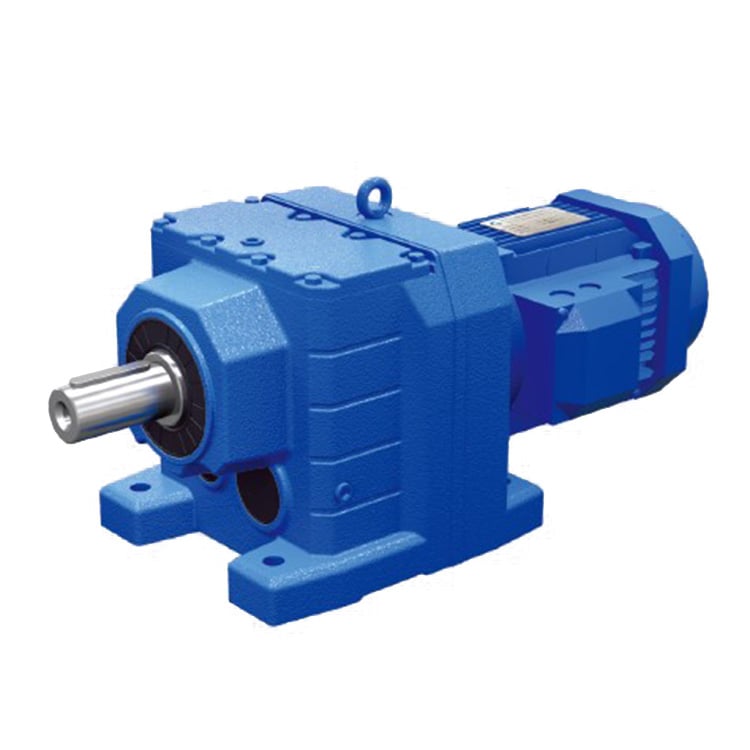

Xwd Bwd Pin Wheel Planetary Cycloidal Speed Reducer

Gearbox with Electric Motor

Chinese electric motor speed reducer is widely used in mining machinery, chemical industry,steel metallurgy, light

industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

Main Series Product: R series helical gear motor reducer, K series spiral bevel gear reducer, NGW, P series planetary gear reducer, H B series helical gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gearbox reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloidal speed reducer, etc. Meanwhile, map sample processing business can be undertaken.

Product Description

1. Big Volecity- Reducing Ratio:Ratio of single-stage speed-reducing is 1/11-1/87; Ratio of double stage speed-reducing is 1/112-1/5133;Ratio of three-stage speed-reducing is 1/2057-1/446571;more-stages can be combined according to the requirement.

2. High driving efficiency:Due to adopting rolling engagement in falling-in part, the driving efficiency can reach above 90%.

3. Small in size, light weight: with compacted structure,small size and light weight. Due to adopting the principle of planet driving so that the input and output shaft in the same axis which will integrated with the motor.

4. Long service life: Has good resistance to abrasion because the main driving engaging parts are made of bearing steel and applying rolling friction.

5. Stable running: for most driving procedure, we adopt multi-teeth falling-in. Then the running will be stable with low noise.

6. Convenient dismounting:reasonable structure and design.

7. Strong overloading ability,anti-compact,suitable for

frequently start and double-side rotation.

Product Parameters

|

MODEL |

X Series |

B Series |

JXJ Series |

|

SIZE |

XWD XWED XLD XLED |

BWD BWED BLD BLED BWY BWEY BLEY |

JXJL JXJW JXJLED JXJWED |

|

RATIO |

Single Stage: 87 Double Stage: |

||

|

SPEED RPM |

Single Stage: 136/91 88/59 60/40 52/35 43/29 38/23 25/17 21/14 17/12 Double Stage: 12.4 8 5.2 4.7 3.2 2.5 2 1.8 1.5 1.2 1 0.8 0.7 0.6 0.4 0.3 |

||

|

MOTOR POWER |

0.55kw 0.75kw 1.5kw 2.2kw 3kw 4kw 5.5kw 7.5kw 11kw 15kw 18.5kw 22kw 30kw 37kw 45kw 55kw |

||

Model selection for washing machine Gear Box Transmission:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide. industrial helical gearbox. H PV series High quality Right Angle Unique speed reducer HB helical gearbox / gear box.

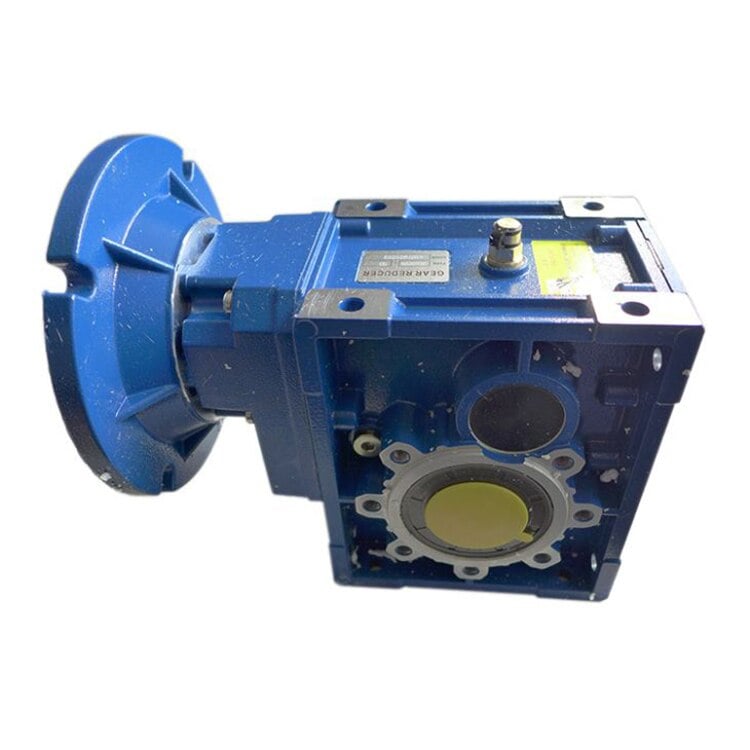

Detailed Photos

Chinese Gearbox Speed Reducer is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm reducer, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy(metal mills like plate flip machines, ingot pushers, winding machines,cooling bed transfer frames, roller straighteners, roller tables, shears continuous, casting drivers, slabbing mills, wire mills, sheet mills, plate mills), nonferrous metals, coal, building materials, ships, water conservancy(screw pumps, water turbines, centrifugal pumps, raking equipment, aerators, filter presses), electricity, construction machinery, chemical industry (extruders, dough mill, rubber calender, cooling drums, mixers, agitators, toasters, centrifuges), Cranes(slewing gears, luffing gears, travelling gears, hoisting gears), Cane sugar mills, paper machines,cooling towers,dredgers(dumping devices, travelling gears, bucket wheel excavators, cutter heads, traversing gears), conveyors(bucket conveyors, hauling winches, hoist, belt conveyors, goods lifts, apron conveyors, rail travelling gears, escalators), Plate bending machines, cement industry (concrete mixers, breakers, rotary kilns, tube mills, separators, roll crushers) and petrochemical industries.

In all fields of national economy and national defense industry, gearbox reducer products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products.

Packaging & Shipping

Application

| Driven machines | |||

| Waste water treatment | Thickeners,filter presses,flocculation apparata,aerators,raking equipment,combined longitudinal and rotary rakes,pre-thickeners,screw pumps,water turbines,centrifugal pumps | Dredgers | Bucket conveyors, dumping devices, carterpillar travelling gears, bucket wheel excavators as pick up, bucket wheel excavator for primitive material, cutter head, traversing gears |

| Chemical industry | Plate bending machines, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges | Metal working mills | plate tilters, ingot pushers, winding machines, cooling bed transfer frames, roller straigheners, table continuous intermittent, roller tables reversing tube mills, shears continuous, casting drivers, reversing CZPT mills |

| Metal working mills | Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives | Conveyors | Bucket conveyors, hauling winches, hoists, belt conveyors, good lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters | Reciprocating compressors | ||

| Cranes | Slewing gears, luffing gears, travelling gears, hoisting gear, derricking jib cranes | Cooling towers | Cooling tower fans, blowers axial and radial |

| Cane sugar production | Cane knives, cane mills | Beet sugar production | Beet cossettes macerators, extraction plants, mechanical refrigerators, juice boilers, sugar beet washing machines, sugar beet cutter |

| Paper machines | Pulper drives | Cableways | Material ropeways, continuous ropeway |

| Cement industry | Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers | ||

Company Profile

Established in 1995 , HangZhou Boji Machinery is a professional manufacturer and exporter that is concerned with the design, development and production of Gearbox Speed Reducer. We are located in HangZhou of ZheJiang Province, with convenient transportation access. With our own brand “TianQi”, all of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Our company possesses complete machining center, lathe, gear shaping machine, gear milling machine, gear grinding machine and assembling lines. Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction.

Besides, In 2005,we attained ISO9001 certification. As a result of our high quality products and outstanding customer service, we have gained a global sales network CZPT South America, Saudi Arabia, Vietnam, Pakistan, Philippines, South Africa and other countries and regions.

With rich export experience, high quality products, competitive prices, good service and in-time delivery, we certain that we can meet all of your requirement and exceed your expectations. Our feature is bright with new cooperative relationships with companies from all over the world. We look CZPT to speaking with you to future discuss how we can be of service to you.

FAQ

1. Who are we?

We are the Factory, with over 25 years of production experience, based in ZheJiang , China, start from 1995,sell to Domestic Market(50.00%),Mid East(10.00%),Southeast Asia(10.00%),Western Europe(5.00%),South America(5.00%),Eastern Europe(5.00%),Eastern Asia(5.00%),North America(3.00%),Africa(2.00%),Southern Europe(2.00%),South Asia(2.00%),Central America(1.00%).

2. Can you customize according to our requirements?

Yes, we can design nonstandard products according to customer’s drawing and sample.

3.What can you buy from us?

speed reducer,gearbox,gear motor,pump,crusher

4. Why should you buy from us not from other suppliers?

Founded in 1995, with over 20 years of production experience and credibility. With professional engineer team, advanced technology production and skilled workers.Specialized in the production of reducer. Map sample processing business can be undertaken.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

| Application: | Motor, Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Layout: | Coaxial |

| Gear Shape: | Cycloidal Gear |

| Step: | Double-Step |

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Advantages and disadvantages of worm gear reducer gearbox

If you are looking for a worm gear reducer gearbox, you have come to the right place. This article will cover the pros and cons of worm gear reducer gearboxes and discuss the different types available. You will learn about multi-head worm gear reducer gearboxes, hollow shaft worm gear reducer gearboxes as well as hypoid gear sets and motors.

Hollow shaft worm gear reducer gearbox

Hollow shaft worm gear reducer gearboxes are used to connect two or more rotating parts. They are available in single-axis and dual-axis versions and can be connected to various motor types. They can also have different ratios. The ratios of these gear reducer gearboxes depend on the quality of the bearings and assembly process.

Hollow shaft worm gear reducer gearboxes are made of bronze worm gears and cast iron hubs. The gears are lubricated with synthetic oil. They are lightweight and durable. They can be installed in various engine housings. Additionally, these gear reducer gearboxes are available in a variety of sizes. The range includes 31.5, 40, 50, 63, and 75mm models. Other sizes are available upon request.

In addition to worm gear reducer gearboxes, there are also helical gear reducer gearboxes. These reducer gearboxes can achieve very low output speeds. They are also suitable for all-around installations. In addition, the advantage of a multi-stage reducer gearbox is that it is more efficient than a single-stage gear reducer gearbox. They also feature low noise, low vibration, and low energy consumption.

Hollow shaft worm gear reducer gearboxes are generally less expensive and last longer. They are also a suitable replacement for solid shaft gearboxes for machines that require high torque without compromising strength. Typical gear arrangements include worm, spur, helical and bevel gears. Gear ratio is the ratio of input torque to output torque.

Multi-head worm gear reducer gearbox

The multi-head worm gear reducer gearbox is used to reduce the speed of the machine. It uses friction to hold the worm in place while transmitting power. These gears can also be called ground worms and hardened worm gears. They are useful in conveying systems and most engineering applications.

Multiple worm reducer gearboxes have a large number of gear ratios. These gear designs have a central cross-section that forms the front and rear boundaries of the worm gear. This design is a better choice than other worm gears because it is less prone to wear and can be used with a variety of motors and other electronics.

Adjustable multi-head worm gear reducer gearbox to reduce axial play. Usually, the backlash on the left and right sides of the worm is the same. However, if you need less backlash, you can buy a double lead worm gear. This design is ideal for precision applications requiring small clearances. The lead of the opposing teeth of the double worm gear is different from the right side, so the backlash can be adjusted without adjusting the center distance between the worm gears.

Worm gear reducer gearboxes are available from a variety of manufacturers. Many gear manufacturers stock these gears. Since the gear ratios are standardized, there is no need to adjust the height, diameter, or length of the shaft. Worm gears have fewer moving parts, which means they require less maintenance.

Hypoid Gear Set

Worm gears are the most common type of gear. While these gears are great for high-to-low ratios, hypoid gear sets are much more efficient in all ratios. This difference is due to higher torque density, better geometry and materials, and the way hypoid gears transmit force differently than worm gears.

Hypoid gear sets have curved helical teeth. This results in smooth gear meshing and little noise. This is because the hypoid gears start to slowly contact each other, but the contact progresses smoothly from tooth to tooth. This reduces friction and wears, thereby increasing the efficiency of the machine.

The main advantages of hypoid gears over worm gears are higher torque capacity and lower noise levels. Although their upfront cost may be higher, hypoid gears are more efficient than worm gears. They are able to handle higher initial inertia loads and can deliver more torque with a smaller motor. This saves money in the long run.

Another advantage of hypoid gears is the lower operating temperature. They also do not require oil lubrication or ventilation holes, reducing maintenance requirements. The hypoid gear set is maintenance-free, and the grease on the hypoid gear set lasts for decades.

Hypoid gear motor

A hypoid gear motor is a good choice for a worm gear reducer gearbox as it allows for a smaller motor and more efficient energy transfer. In fact, a 1 hp motor driving a hypoid reducer gearbox can provide the same output as a 1/2 hp motor driving a worm reducer gearbox. A study by Agknx compared two gear reduction methods and determined that a hypoid gear motor produces more torque and power than a worm reducer gearbox when using a fixed reduction ratio of 60:1. The study also showed that the 1/2 HP hypoid gear motor is more energy efficient and reduces electricity bills.

Worm reducer gearboxes run hotter than hypoid gears, and the added heat can shorten their lifespan. This can cause components to wear out faster, and the motor may require more frequent oil changes. In addition, hypoid gear motors are more expensive to manufacture.

Compared to worm gears, hypoid gears offer higher efficiency and lower operating noise. However, they require additional processing techniques. They are made of bronze, a softer metal capable of absorbing heavy shock loads. Worm drives require work hardening and are less durable. Operating noise is reduced by up to 30%, and hypoid gears are less prone to breakage than bevel gears.

Hypoid gear motors are prized for their efficiency and are used in applications requiring lower torque. A unique hypoid tooth profile reduces friction. In addition, hypoid gear motors are ideal for applications where space is limited. These geared motors are often used with pulleys and levers.

R series worm gear reducer gearbox

R series worm gear reducer gearboxes have a variety of characteristics that make them ideal for different applications. Its high rigidity cast iron housing and rigid side gears are designed for smooth drive and low noise. It also features high load capacity and long service life. Additionally, it can be assembled into many different configurations as required.

High efficiency, large output torque and good use efficiency. It comes in four basic models ranging from 0.12KW to 200KW. It can be matched with right angle bevel gearbox to provide large speed ratio and high torque. This combination is also suitable for low output and high torque.

AGKNX Electric Worm Gear reducer gearbox

AGKNX Electric worm gear reducer gearboxes are available with NEMA C-face mounting flanges for a variety of motors. These reducer gearboxes feature double lip oil seals, an aluminum alloy housing, and two bearings on the input and output shafts. These reducer gearboxes are rust-proof and have epoxy paint on the inside. They are available in a variety of ratios, from 7.5:1 to 100:1.

Worm reducer gearboxes are one of the most cost-effective and compact gears. These reducer gearboxes increase output torque while reducing input speed. AGKNX Electric’s worm gear reducer gearboxes are pre-installed with Mobil SHC634 Synthetic Gear Oil. These reducer gearboxes have an internal oil gallery guide to protect the shaft. They also have a one-piece cast iron housing.

AGKNX Electric Corporation is the leading independent distributor of electric motors in the United States. They have eight strategically located warehouses, enabling them to ship most orders on the same day. They offer motors of various sizes up to 20,000 hp. They also offer a variety of motor controls and variable speed drives.

editor by CX 2023-05-22

China Best Sales Newstart rotovator electric motor speed planetary reducer gearbox with motor with Good quality

Warranty: 3 years

Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Japan Car Front Drive Shaft For LAND CRUISER PRADO 43430-60080 Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company, Servo Motor

Weight (KG): 7 KG

Customized support: OEM

Gearing Arrangement: Planetary

Output Torque: Can be customized, Depended on the servo motor

Input Speed: Can be customized, Depended on the servo motor

Output Speed: Can be customized, Depended on the Ratio

Product name: Planetary Gearbox

Ratio: 3, For Seadoo CZPT Carbon Ring Kit , Bellow GTI GTX WAKE 130 155 170 OEM295501197 271001933 4,5,6,8,10

Input interface: According to motor output

No-load torque at 20oC (Nm): ≤0.1Nm

Normal Input Speed: 1500r/min

Max. Input Speed: 3000r/min

Max. Radial Load: 18000N

Max. Axial Load: 28000N

Noise: ≤72db

Protection grade (IP): IP54

Packaging Details: Foam box, carton packaging, or according to customer requirements

Port: HangZhou, HangZhou

Product Nameplanetary gearboxBrand NameNEWSTARTApplicable IndustriesServo MotorGearing ArrangementPlanetaryRatio i3,4,5, Vibratite Flex Extension Bar Set, Bendable Elastic Joint Head Post Connecting Link, Shaft Drive Adapter Bit Holder 6,8,10Input interfaceAccording to motor outputMax. radial load (N)18000Max. axial load (N)28000Rated input speed (r/min)1500r/minMax. input speed (r/min)3000r/minNoise (db)≤72dbBacklash – Class P2 (arcmin)≤8arcminNo-load torque at 20oC (Nm)≤0.1NmOperating temperature (℃)-15 to +40℃Service life (h)≥20,000hProtection grade (IP)IP54MOQ1 More Products Product Line Our Company Certifications Exhibition Packaging & Shipping FAQ Q: Are you a manufacturer or a trader? A: We are a professional factory with 16 years of production experience. Q: Are all motor types compatible with planetary reducers? A: Our planetary gear reducers are customized according to your motor mounting flange, CZPT China Nylon Snap Bushing Plastic Cable Management Grommet all types of motors can be matched. Q: What is the warranty period of the product? A: The warranty period of the product is 18 months. Q: What is the delivery cycle of the product? A: The delivery time of general products is 20-25 days. Customized products in about 45 days. Please ask for specific delivery time before ordering. If you have other questions that are not clear, you are welcome to contact us.

What Is a Gearbox?

There are several factors to consider when choosing a gearbox. Backlash, for example, is a consideration, as it is the angle at which the output shaft can rotate without the input shaft moving. While this isn’t necessary in applications without load reversals, it is important for precision applications involving load reversals. Examples of these applications include automation and robotics. If backlash is a concern, you may want to look at other factors, such as the number of teeth in each gear.

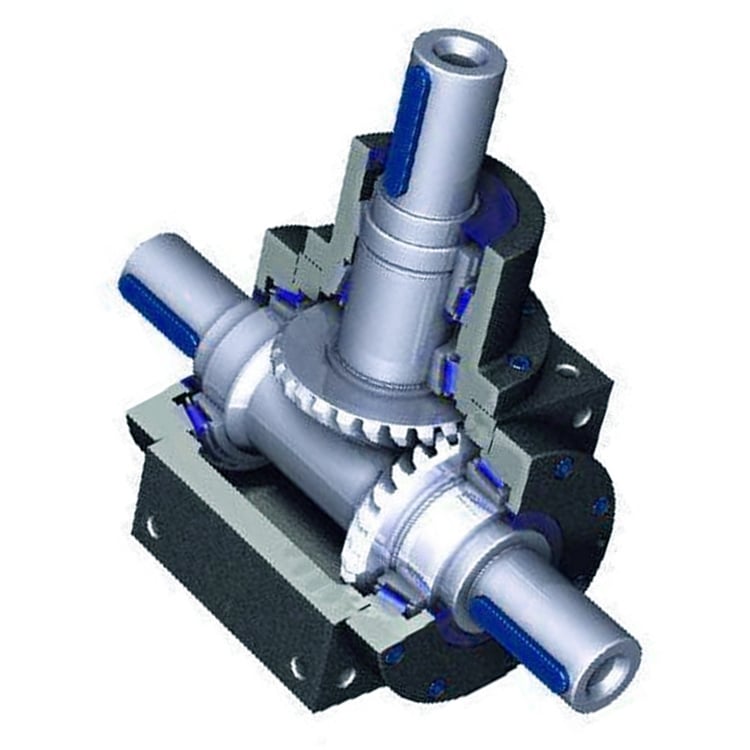

Function of a gearbox

A gearbox is a mechanical unit that consists of a chain or set of gears. The gears are mounted on a shaft and are supported by rolling element bearings. These devices alter the speed or torque of the machine they are used in. Gearboxes can be used for a wide variety of applications. Here are some examples of how gearboxes function. Read on to discover more about the gears that make up a gearbox.

Regardless of the type of transmission, most gearboxes are equipped with a secondary gear and a primary one. While the gear ratios are the same for both the primary and secondary transmission, the gearboxes may differ in size and efficiency. High-performance racing cars typically employ a gearbox with two green and one blue gear. Gearboxes are often mounted in the front or rear of the engine.

The primary function of a gearbox is to transfer torque from one shaft to another. The ratio of the driving gear’s teeth to the receiving member determines how much torque is transmitted. A large gear ratio will cause the main shaft to revolve at a slower speed and have a high torque compared to its counter shaft. Conversely, a low gear ratio will allow the vehicle to turn at a lower speed and produce a lower torque.

A conventional gearbox has input and output gears. The countershaft is connected to a universal shaft. The input and output gears are arranged to match the speed and torque of each other. The gear ratio determines how fast a car can go and how much torque it can generate. Most conventional transmissions use four gear ratios, with one reverse gear. Some have two shafts and three inputs. However, if the gear ratios are high, the engine will experience a loss of torque.

In the study of gearbox performance, a large amount of data has been collected. A highly ambitious segmentation process has yielded nearly 20,000 feature vectors. These results are the most detailed and comprehensive of all the available data. This research has a dual curse – the first is the large volume of data collected for the purpose of characterization, while the second is the high dimensionality. The latter is a complication that arises when the experimental gearbox is not designed to perform well.

Bzvacklash

The main function of a gearhead is to multiply a moment of force and create a mechanical advantage. However, backlash can cause a variety of issues for the system, including impaired positioning accuracy and lowered overall performance. A zero backlash gearbox can eliminate motion losses caused by backlash and improve overall system performance. Here are some common problems associated with backlash in gearheads and how to fix them. After you understand how to fix gearbox backlash, you’ll be able to design a machine that meets your requirements.

To reduce gearbox backlash, many designers try to decrease the center distance of the gears. This eliminates space for lubrication and promotes excessive tooth mesh, which leads to premature mesh failure. To minimize gearbox backlash, a gear manufacturer may separate the two parts of the gear and adjust the mesh center distance between them. To do this, rotate one gear with respect to the fixed gear, while adjusting the other gear’s effective tooth thickness.

Several manufacturing processes may introduce errors, and reducing tooth thickness will minimize this error. Gears with bevel teeth are a prime example of this. This type of gear features a small number of teeth in comparison to its mating gear. In addition to reducing tooth thickness, bevel gears also reduce backlash. While bevel gears have fewer teeth than their mating gear, all of their backlash allowance is applied to the larger gear.

A gear’s backlash can affect the efficiency of a gearbox. In an ideal gear, the backlash is zero. But if there is too much, backlash can cause damage to the gears and cause it to malfunction. Therefore, the goal of gearbox backlash is to minimize this problem. However, this may require the use of a micrometer. To determine how much gearbox backlash you need, you can use a dial gauge or feeler gauge.

If you’ve been looking for a way to reduce backlash, a gearbox’s backlash may be the answer. However, backlash is not a revolt against the manufacturer. It is an error in motion that occurs naturally in gear systems that change direction. If it is left unaccounted for, it can lead to major gear degradation and even compromise the entire system. In this article, we’ll explain how backlash affects gears and how it affects the performance of a gearbox.

Design

The design of gearboxes consists of a variety of factors, including the type of material used, power requirements, speed and reduction ratio, and the application for which the unit is intended. The process of designing a gearbox usually begins with a description of the machine or gearbox and its intended use. Other key parameters to consider during gearbox design include the size and weight of the gear, its overall gear ratio and number of reductions, as well as the lubrication methods used.

During the design process, the customer and supplier will participate in various design reviews. These include concept or initial design review, manufacturing design validation, critical design review, and final design review. The customer may also initiate the process by initiating a DFMEA. After receiving the initial design approval, the design will go through several iterations before the finalized design is frozen. In some cases, the customer will require a DFMEA of the gearbox.

The speed increaser gearboxes also require special design considerations. These gearboxes typically operate at high speeds, causing problems with gear dynamics. Furthermore, the high speeds of the unit increase frictional and drag forces. A proper design of this component should minimize the effect of these forces. To solve these problems, a gearbox should incorporate a brake system. In some cases, an external force may also increase frictional forces.

Various types of gear arrangements are used in gearboxes. The design of the teeth of the gears plays a significant role in defining the type of gear arrangement in the gearbox. Spur gear is an example of a gear arrangement, which has teeth that run parallel to the axis of rotation. These gears offer high gear ratios and are often used in multiple stages. So, it is possible to create a gearbox that meets the needs of your application.

The design of gearboxes is the most complex process in the engineering process. These complex devices are made of multiple types of gears and are mounted on shafts. They are supported by rolling element bearings and are used for a variety of applications. In general, a gearbox is used to reduce speed and torque and change direction. Gearboxes are commonly used in motor vehicles, but can also be found in pedal bicycles and fixed machines.

Manufacturers

There are several major segments in the gearbox market, including industrial, mining, and automotive. Gearbox manufacturers are required to understand the application and user industries to design a gearbox that meets their specific requirements. Basic knowledge of metallurgy is necessary. Multinational companies also provide gearbox solutions for the power generation industry, shipping industry, and automotive industries. To make their products more competitive, they need to focus on product innovation, geographical expansion, and customer retention.

The CZPT Group started as a small company in 1976. Since then, it has become a global reference in mechanical transmissions. Its production range includes gears, reduction gearboxes, and geared motors. The company was the first in Italy to achieve ISO certification, and it continues to grow into one of the world’s leading manufacturers of production gearboxes. As the industry evolves, CZPT focuses on research and development to create better products.

The agriculture industry uses gearboxes to implement a variety of processes. They are used in tractors, pumps, and agricultural machinery. The automotive industry uses gears in automobiles, but they are also found in mining and tea processing machinery. Industrial gearboxes also play an important role in feed and speed drives. The gearbox industry has a diverse portfolio of manufacturers and suppliers. Here are some examples of gearboxes:

Gearboxes are complex pieces of equipment. They must be used properly to optimize efficiency and extend their lifespan. Manufacturers employ advanced technology and strict quality control processes to ensure their products meet the highest standards. In addition to manufacturing precision and reliability, gearbox manufacturers ensure that their products are safe for use in the production of industrial machinery. They are also used in office machines and medical equipment. However, the automotive gearbox market is becoming increasingly competitive.

China Good quality Helical Gear Reducer High Speed Planetary Reduction Gearbox for Industrial Using with Hot selling

Product Description

Planetary Series High Electricity Equipment Box

Housing is manufactured of cast iron,which enhance its rigidity and anti-vibration.

Sun and plant gears are processed by cementite and hardening,gears are procedures by grinding,which increase the performance and life time of the gearbox.

Input manner:coaxial input,helical equipment enter,bevel-helical gear enter.

Output mode:inside involute spline,hollow shaft with shrink disk,exterior involute spline,reliable shaft with flat important.

Mounting manner:Horizonal vertical,torque-arm.

P series sizes 9~34 transmission phase:2~3 ratio:25~4000

Ratio will be more substantial in combination with H,R,K sequence.

RFQ

Q:Are you investing company or company?

A: We are maker with more than twenty years’ encounter.

Q: How long is your shipping time?

A: Usually it is in 10 times if the items are in inventory, for merchandise made as for every purchase, it is in 35 days soon after affirmation of get.

Q: How prolonged must I hold out for the opinions right after I send the enquiry?

A: Normally within twelve several hours.

Q: What info should I give you to confirm the item?

A: Product/Dimensions, Transmission Ratio, Velocity, Shaft instructions & Buy amount and many others.

Q: Hong long is your product guarantee?

A: We provide 12 months warranty from departure day of the goods.

Q: What is your payment phrases? T/T a hundred% in CZPT for quantity much less than USD10000.-, thirty% T/T in CZPT , harmony prior to cargo for quantity over USD10000.

If you have any other questions, make sure you come to feel free to contact us beneath:

HOW TO Get in touch with US?

Deliver your Inquiry Specifics in the Beneath, click on “Send” Now!

Gearboxes go by numerous different names, like equipment drives, pace reducers, equipment reducers, velocity reducers, and gear motors. All conditions are employed interchangeably when referring to inline gear reducers. Our inventory consists of a extensive selection of equipment reducers for higher speed, substantial precision apps with enter speeds up to 4000 RPM.

Gearboxes can be utilised in a variety of fields of comprehensive processing, agriculture, chemical processing, oil and gasoline, power transmission and distribution methods, logistics, warehousing and other industries. Equipment reducers are usually utilized the place greater torque and/or reduced rotational speeds are essential, or if power needs to be transmitted at alternating angles, such as in correct-angle motors. It can also adjust the path of rotation, as nicely as clockwise and counterclockwise. EP provides a comprehensive range of gear reducers with right angle worms and substantial effectiveness possibilities. Electrical Equipment Aluminum items are a lightweight and sturdy different to present day forged iron and metal designs and can be stocked or custom produced to your exact specifications. EP gearboxes are light-weight and durable, aluminum worm gearboxes are developed for tight spaces, like challenging-to-put in OEM patterns as nicely as mobile equipment. Eccentric reducers are available as compact aluminum or forged iron inline reducers with seal life rankings from 15HP (aluminum) to 40HP (cast iron). In addition to our common and modified standard items, our engineers will operate with you to design and develop custom made solutions for numerous generate systems to go well with your application wants.

China Hot selling Automatic Power Transmission Gear Reducer Planetary Gearbox Speed Reduction for Gear Motors with Free Design Custom

Merchandise Description

Technical services:

- According to the appropriate parameters offered by the consumer, the SIGRINER engineering software is utilized to produce the movement load curve diagram of the system products to get the corresponding parameters and derive the motion load curve. Intuitively show essential parameters and load indexes in the transmission technique to assist buyers have out sensible structural style.

- SIGRINER offers a motor databases from 500 servo motor companies around the world

Buyer instruction:

We are honored to provide you with our utilized computing and transmission style knowledge. We can give appropriate training according to your requirements. We can supply relevant coaching according to your wants.

Certain

| STAGE | 2 | |||||||||

| Gear ratio | i | twenty | 20 | 25 | 30 | forty | 50 | 70 | 70 | |

| Rated output torque (one thousand moments is authorized in gear box) |

T 2N | Nm | 19 | 19 | 22 | 20 | 17 | 22 | 19 | fourteen |

| In.lb | 177 | 168 | 195 | 177 | 150 | 195 | 168 | 124 | ||

| T 2NOt | Nm | 1.5xNOM.Output/ 1.5 instances rated output torque | ||||||||

| In.lb | ||||||||||

| Rated input RPM (T2N, 20ºC environment temperature) b | N 1n | rpm | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 |

| Max. Enter RPM | N 1max | rpm | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 |

| Max.backlash | J t | arcmin | PBMD40≤5 ARCMIN | |||||||

| Max.radical drive | F 2AMAX | N | 300 | |||||||

| ibf | 68 | |||||||||

| Max.axial drive | F 3RMAX | N | 180 | |||||||

| ibf | 40.five | |||||||||

| Function lifestyle | L h | hr | ≥20000 | |||||||

| Totally loaded effectiveness | η | % | 95 | |||||||

| Environment temperature | ºC | -fifteen to 40 | ||||||||

| F | 5 to 104 | |||||||||

| Allowable highest temperature of shell |

ºC | +90 | ||||||||

| F | 194 | |||||||||

| Lubrication | Life Lubrication | |||||||||

| Rotation course | Input/output with exact same direction | |||||||||

| Safety class | IP65 | |||||||||

| Installation direction | Any/ any direction | |||||||||

| Operating noise (i=10 and n1=3000rpm no-load) |

Lpa dB(A) | ≤65 | ||||||||

| Moment of inertia | J1 | Kg.cm² | .three | .3 | .3 | .3 | .three | .3 | .three | .three |

| 10-3in.lb.s2 | .three | .3 | .three | .three | .three | .three | .three | .three | ||

Sector application

- We offer fast source and robust help all in excess of the planet by means of a complete sales and support community

- With years of prosperous expertise, our authoritative experts provide market place-major consulting providers for various industrial sectors

- Robotics, automation and manipulator engineering

A range of servo gearboxes and mechanical transmission systems, from economical to high-stop types can be applied to a variety of robots and their auxiliary axes, these kinds of as transmission shafts and station handle gadgets

Printing device

Modern gearbox ensures balance, synchronization accuracy and prolonged-time period precision even at large speeds

The ideal solution for large-good quality printing processes and other continuous duty purposes

Choice: built-in sensor for checking paper tension and comparable parameters

Appropriate angle gearboxes (worm and planetary gears) are sturdy and can be utilised for 90° turns. An inline reducer (parallel shaft and planetary) is an excellent matching motor with substantial enter speeds, or when equipment motor effectiveness is crucial. Get in touch with our technical revenue employees to support figure out which transmission solution is ideal for you.

Gear reducers are also referred to as reducers. Mechanical components, by possibly of these two names, are created to lessen the energy transferred amongst the motor and the machine between the rotational speeds (revolutions per moment). The reducer efficiently minimizes the rotational pace developed by the motor, therefore managing the pace at which the device runs and escalating the torque developed by the motor. Multiplying the torque produced by the motor raises the machine’s available energy – a approach acknowledged as “mechanical dominance”. In a larger context, equipment reducers are essentially tools utilized to boost the effectiveness of equipment operation.

China OEM Ud (L) Series Planetary Mechanical Infinite Speed Reducer Variable Speed Gearbox wholesaler

Product Description

UD(L) collection Planetary mechanical infinite velocity reducer variable pace gearbox

Manufacturing description:

UDL collection speed variator design and style is compromised the worldwide sophisticated engineering. The principal characteristics of UDL pace variator as pursuing:

| Change velocity precision | .5-1 rpm/min |

| Pace ratio | 1: 1.4 to 1: 7 |

| Features | Very good energy and extended life software |

| Alter the velocity Conveniently | |

| Could be operating continually, positive and unfavorable managing right, clean in driving, secure in overall performance and low in noise. | |

| Total in sealing and suited for any setting | |

| Compact in construction and small. | |

| Higher-high quality aluminium alloy die casting into condition, good-seeking in visual appeal, gentle in bodyweight and it by no means gets rusty. | |

| Excellent in adaptation | UDL series variator can be blended with all kinds of pace reducers, as to attain lower stepless speed-altering. |

Parameters:

| Types | Energy | Ratio | Output speed(n2)* | Output torque | Output shaft dia. | Output flange dia. |

| Udl002 | .18kw | 1.6~8.two | 800~170r/min | 1.5~3n. M | Φ11 | Φ140 |

| Udl005 | .25kw | 1.4~seven | a thousand~200r/min | 2.2~6n. M | Φ14 | Φ160 |

| Udl005 | .37kw | 1.4~seven | 1000~200r/min | three~6n. M | Φ14 | Φ160 |

| Udl571 | .55kw | 1.4~seven | one thousand~200r/min | four~8n. M | Φ19 | Φ200 |

| Udl571 | .75kw | one.4~7 | 1000~200r/min | 6~12n. M | Φ19 | Φ200 |

Commeicial info:

| MOQ | one Piece |

| Deal | Plywood Circumstance/Wood Circumstance |

| Supply | 20-twenty five times |

| Payment Conditions | FOB, CIF, CFR |

| Payment Methods | T/T, 30% in advance, 70% just before shipping |

| Shipping Port | ZheJiang |

Material:

Housing: Aluminium or ht250 forged iron.

Gear: 20crmnti h, high grade allo with carburization, surface area hardness: fifty eight-62HRC, middle hardness: 33-48HRC

Grinding precision grade: ISO1328-1: 1995 course 5-6, surfaceness: .8, carburization depth: .6-1.5mm

Bearing: 42CrMo

Business profile:

Business: HangZhou CZPT machinery Co., Ltd—a joint-venture organization

Employmee: Far more than 3000, complex personnel have 1/3 intotal

Company scope: P/RV/R/F/K/HB sequence equipment units, AC motor and micro-planetary gearbox, ATA sequence hanging shaft-mounted gearbox

Factory sq.: .6million square meters

Market share: South The usa, Europe, the Center East, southeast Asia and other countries

Our Superiority:

one. Shipping and delivery on Time.

2. Expert Support: Tailored is our gain.

3. Good Good quality.

4. Rapidly and Low Expense Deliver: Lengthy-time period cooperated transport forwarders.

Our Services:

| Pre-sale providers | one. Decide on equipment product. |

| two.Design and manufacture merchandise according to clients’ particular necessity. | |

| three.Teach complex personal for consumers | |

| Services in the course of promoting | one.Pre-verify and settle for products forward of shipping and delivery. |

| 2. Help clientele to draft resolving ideas | |

| After-sale solutions | one.Assist customers to get ready for the initial development plan. |

| 2. Prepare the very first-line operators. | |

| 3.Take initiative to eliminate the difficulty speedily. | |

| 4. Offer complex exchanging. |

Buyer browsing:

FAQ:

1.Q:What types of gearbox can you produce for us?

A:Principal products of our organization: UDL sequence speed variator,RV sequence worm gear reducer, ATA series shaft mounted gearbox, X,B sequence equipment reducer,

P series planetary gearbox and R, S, K, and F series helical-tooth reducer, far more

than 1 hundred versions and countless numbers of specs

two.Q:Can you make as for every custom drawing?

A: Indeed, we offer you personalized services for customers.

three.Q:What is your terms of payment ?

A: 30% CZPT payment by T/T following signing the agreement.70% ahead of supply

four.Q:What is your MOQ?

A: 1 Set

If you have any need for our goods you should come to feel cost-free to contact me

When hunting at a reducer vs a gearbox, typically the only variation is terminology. This is since all reducers are gearboxes. Nevertheless, not all gearboxes are retarders. This may possibly seem complex, but it really is really fairly simple. A reducer is a gear set amongst the motor and the equipment. The function of the reducer is to decrease the rotational pace transferred between these two endpoints. The reducer amplifies and multiplies the torque (enter) created by the motor. Next, a reducer, as the title implies, minimizes the pace of the enter (output in rpm) so that the output is the proper velocity. The term “gearbox” is just a generic phrase used for the gear prepare amongst the motor and the equipment. Consequently, all reducers are gearboxes. Nonetheless, not all gearboxes decrease enter speed. Though unusual, gearboxes can truly increase input speeds. By considerably the most common type of gearbox is a retarder, but it would be incorrect to say that all gearboxes are retarders.

The time period “gearbox” is employed to refer to any device that connects a motor to a device and is composed of a series of gears, also recognized as a equipment established. It gets the major enter velocity from the motor and modifications it to a different output velocity using its gears. Different kinds and combos of gears serve certain functions. The types of gears identified in gearboxes consist of spur gears, bevel gears, helical gears, helical gears and worm gears. The efficiency efficiency of a gearbox is represented by the gearbox ratio, which is the ratio of the speed of the input supply to the speed of the output supply

in Cuiaba Brazil sales price shop near me near me shop factory supplier Asge-060 Planetary Gear Speed Reducer Ratio 10: 1 manufacturer best Cost Custom Cheap wholesaler

Every procedure, every area, each perform in EPG is demanded to be done a single action adhering to an additional, cautiously and cautiously, from content variety, reformation to producing components, from components warmth remedy to automatic assembly, from good quality control to merchandise inspection and tests and from get dealing to after revenue services. Great consideration has been paid out on environmental protection and energy preserving. It has recognized steady cooperation with several properly recognized universities and institutes in china such as, Zhejiang University, Jilin College, Technical committee of nationwide chain drive regular, Institute of national chain travel, Zhejiang application engineering content institute, Huhan substance defense institute and it cooperated to identified China 1st Auto chain institute with Nationwide chain drive institute.

Specification:

| Product Variety: | ASGE-060 |

| Ratio: | ten |

| Norminal Output Torque: | 30Nm |

| Unexpected emergency Quit Torque: | 2.5 moments of Nominal Output Torque |

| Nominal Input Speed: | 5000rpm |

| Max.Enter Velocity: | 10000rpm |

| Torsinal Rigidity: | five N.m/arcmin |

| Max. Radial Load: | 1300 N |

| Max. AXiHu (West EPT) Dis.al Load: | 550 N |

| Provider EPT: | 20000 hr |

| EPT Backlash P1: | le3 arcmin |

| Efficiency: | ge95% |

| Set up: | horizontal |

| Shell EPT: | Aluminium alloy |

| EPT EPT: | 42crmo |

two.The advantage of BSG’s EPTT:

(1).The output shaft is produced of massive size,massive span double bearing layout,output shaft and planetary arm bracket as a EPTT.The input shaft is placed directly on the earth arm bracket to ensure that the EPTT has high running precision and maXiHu (West EPT) Dis.mum torsional rigidity.

(2).Shell and the interior ring EPT employed integrated design and style,quenching and tempering right after the processing of the teeth so that it can accomplish high torque,substantial precision,large use resistance.In addition surface area nickel-plated anti-rust treatment,so that its corrosion resistance greatly increased.

(3).The planetary EPT EPTT emploEPTTfull needle roller with no retainer to increase the contact floor,which greatly upgrades structural rigidity and service lifestyle.

(four).The EPT is made of Japanese materials.After the metal cutting procedure,the EPT carburizing heat remedy to 58-62EPTC. And then by the hobbing,Get the very best tooth shape,tooth direction,to make sure that the EPT of high precision and good influence toughness.

(5).Input shaft and EPTTEPT built-in structure,in orEPTTto boost the procedure precision of the EPTT.

3.Software

Be commonly utilised for materials hXiHu (West EPT) Dis.Hu (West EPT) Dis. equipment, engineering EPTTry,metallurgy sector,mining market,petrochemical business, building EPTTry,textile market, medical apparatus and instruments, instrument and meter business,automobile market,maritime industry,weapons market, aerospace area,and so on.

4.About us:

FAQ

Q:What the MOQ of your organization?

A:MOQ is one established.

Q:Could you settle for OEM and personalize?

A:Yes,we can customize for you in accordance to sample or drawing.

Q:Dose your factory have any certification?

A:of course.we have ISO 9001:2008,IQNET and SGS. If you want other like CE,we can do for you.

Q:IS you business manufacturing unit or EPT EPTT?

A:We have our possess manufacturing facility our kind is manufacturing unit trade.

Q: What is the delivery time?

A:It generally requires about 7 doing work times,but the actual shipping time migEPTT be different for diverse orEPTTor at different time.

Q: How does your manufacturing facility do reXiHu (West EPT) Dis.Hu (West EPT) Dis.ding good quality control?

A:EPTT is priority. We alwaEPTTattach fantastic EPTTance to top quality handle from the starting to the end of the production. Each solution will be totally assembled and meticulously tested just before packed .

Q: What is actually your warranty terms?

A:We supply distinct warranty phrases for different merchandise. Remember to make contact with with us for details.

China manufacturer & factory supplier for HangZhou in Coimbatore India EPG WPLF Series Servo Planetary Gearbox Speed Reducer Reduction Gearbox With high quality best price & service

corrosion- and dress in-resistant coiled tubing injector roller chain assemblies for the oil and gas industries. Offered in single and double pitch travel chain varieties with a variety of measurements and electricity ranking. Attributes consist of zinc-nickel and non-hexavalent chromate protecting exterior coating, electrochemically bonded, and interference suit protect plates.More importantly, we make particular components according to equipped drawings/samples and warmly welcome OEM inquiries.

Overview

Quick Specifics

- Relevant Industries:

-

Manufacturing Plant

- GearingIn our income software we offer you regular and broad-angle PTO push shafts. Relating to the customers’ wants there are distinct dimensions, lengths and safety aspects (clutches) obtainable. Arrangement:

-

Helical

- Model Quantity:

-

WPF40, WPF60, WPF90, WPF120, WPF160, WPF180

Offer Ability

- Supply Potential:

- five hundred Established/Sets for each Month

Packaging & Shipping and delivery

- Packaging Specifics

- wooden scenario

- Port

- Shanghai , Ningbo , Shenzhen , Tianjin ect

On the web Customization

Product Information

Solution Description

| Gearing Arrangement | Planetary |

| Location of Origin | China |

| Brand name Name | 202001EPG |

| China | Zhejiang |

| Design Number | WPF40, WPF60, WPF90, WPF120, WPF160, WPF180 |

Solution Show

Solution Screen

Associated Items

EK sequence helical- …

ER sequence helical …

CHC TRC HELICAL GE …

CompanyInfo

Firm Profile

Solution Approach

Creation Process

Certifications

Certifications

consumer-outlined

Cargo & Payment

Our Advantages

A: YoIndustrial Reducers EPG Travel offers two kinds of industrial gearbox, covering regular obligation by way of to heavier obligation and severe obligation purposes observed in some of the world’s most inhospitable mining sites.ur inquiry connected to our items or rates will be replied in 24 hrs.

B: Defense of your sales spot, suggestions of design and all your personal data.

C: Ideal top quality and aggressive value.

……

faq

FAQ

1) How can I place get?

A: You can get in touch with us by e mail about your buy specifics, or area get on line.

2) How can I spend you?

A: After you verify our PI, we will ask for you to spend. T/T (HSBC bank) and Paypal, Western Union are the most normal ways we are making use of.

……

EPG major creation is of farming 15-500 horsepower tractor supporting equipment, mechanical cultivation, harvesting equipment and equipment.