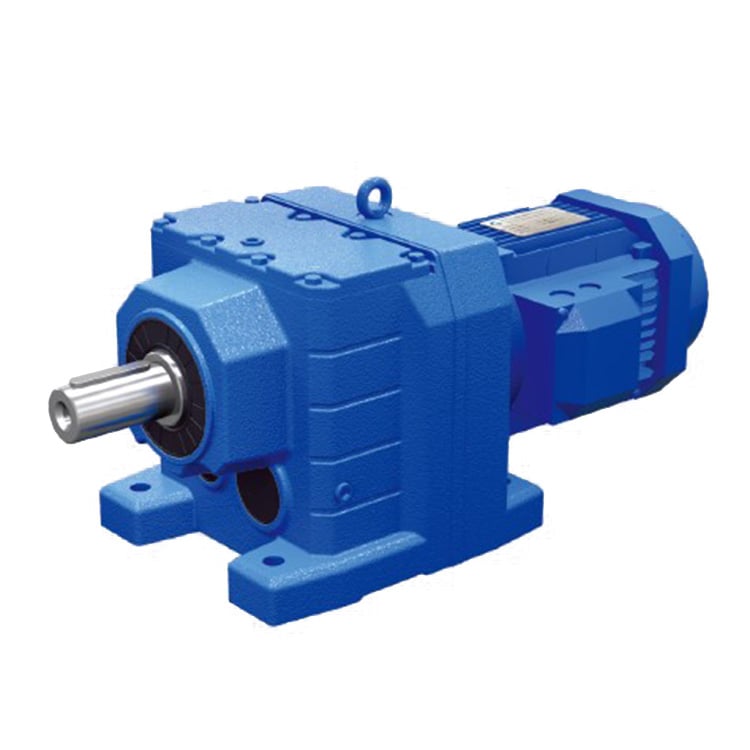

Product Description

Overview

Product Description

Wide Selection of Gearbox Products

The gearbox usually adopts a general design scheme, but in special cases, the design scheme of the gearbox can be changed according to the demands of the user, and it can be modified into an industry-specific gearbox. In the design scheme of the gearbox, the parallel shaft, vertical shaft, general box, and various parts can be changed

Advantages

- Absorption of very high torques and axial forces

- No need for separate thrust housing & bearing.

- Easy alignment (screw directly fits into the vore of gear box)

- Easy to assemble & dismantle.

- Very heavy duty spherical roller thrust bearing is provided.

- Power saving. (you may save up to 20 % power.)

- Less requirement of space.

- For bigger sizes water cooling is provided

- No maintenance required except periodic oil level checking.

- Higher productivity

Features

- Twin Screw Extruder Gearboxes offer the dual shaft counter rotating. The range is available for various center distances

- The gearboxes are available with co-rotating and counter rotating variants

- To work under heavy loading force, the high level dissipation and oil lubrication system are provided. The axial roller type swivel thrust with the thrust bearing coupled in tandem way support the axial thrust

- High torque and high speed output rate

Processing Characteristics of Screw Shaft:

1.Suitable suggestion on material to ensure components performance and extend lifetime of products.

2.Professional technical team can provide surveying and mapping support.

3.All components are finished by CNC machine.

4.Sophisticated quality management system ensure superior quality.

Basic Info.

| Warranty: 1 year | Weight (KG): 500 KG |

| Place of Origin: HangZhou, China |

Gearing Arrangement: helical |

| ratio: 8-20 |

Output Torque: 2*176 |

| standard: JB/T8853-2001 |

Certificate: CE |

| Heat treatment: High-frequency Hardening |

Efficiency: 94%~98%(depends on the transmission stage) |

| Customized support:OEM ODM | Input/output shaft material 40Cr |

| Package: Wooden case |

Mount position: Flange, hollow shaft, CHINAMFG shaft |

| After-sale:Online 24/7 Installation Xihu (West Lake) Dis. | advantage: excellent quality |

| Reduction radio: 3:1 |

Mount Position: Horizontal Foot Mounted Vertical |

| Input Speed: 1500 |

Output Speed: 500 |

Packaging & delivery

|

Packing: wooden case packing |

|

| Port: HangZhou Port |

Applications

X helical gear units for double-screw extruders with parallel drive shafts and the same direction of screw rotation are used mainly in the manufacture of granulates and the refining of raw plastics. Other areas of application include:

- Paint and lacquer industry

- Washing agent industry

- Foodstuff industry (e.g. bread, pasta)

- Animal-feed industry (dog, cat other animal food

Maintenance of the gearbox of the dual-screw extruder

1. The gear box of the dual-screw extruder should be well-ventilated, and the working environment temperature should be within the range of 5-35 °C.

2. Always check the oil quantity of the gear lubricating oil in the box to ensure that the transmission parts in the box are well lubricated.

3. Pay attention to check the bearing parts of the box frequently. The oil temperature of the oil tank of the transmission box should not exceed 70 ºC during operation.

4. The newly put into use gearbox needs to replace the lubricating oil after 250 hours of operation. The oil change time depends on the state of the oil. It is recommended to replace it after 4000-8000 hours of operation or once a year.

5. The gearbox of the dual-screw extruder needs to be regularly maintained and inspected once a year

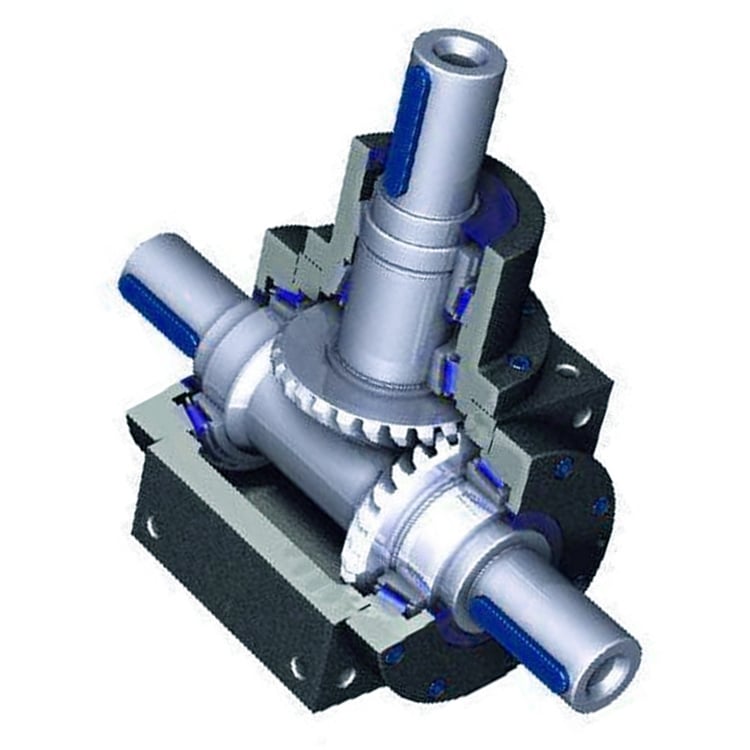

Operating Process

1. The gear on the input shaft is driven by the motor and starts to rotate.

2. The rotating input gear meshes with other gears inside the gearbox, transmitting power.

3. Different-sized gears within the gearbox are combined to form a gear train. Through continuous meshing and rotation, the high-speed, low-torque power from the input shaft gradually converts into low-speed, high-torque output.

4. The output shaft is connected to the last gear and transfers the output torque to the load.

5. Gear reduction gearboxes typically include lubrication and cooling systems to ensure smooth operation and prevent overheating and damage.

6. Our extruder gearbox converts high-speed, low-torque power into low-speed, high-torque output by changing the size ratios and meshing arrangements of different gears, achieving the function of speed reduction.

Types of Gearboxes:

Based on customer requirements, gear reduction gearboxes can be classified according to the size of the output shaft, center distance of the output shaft, output speed, and torque. Alternatively, we can provide several commonly used types of gearboxes for customers to choose from.

Product Service

|

24-hour Hotline

No matter when and where to call we can find our service to you.

|

Pre-sales Consultation

We have 5 sales people online, and whether you have any question can be solved through online communication. |

After-sales Services

Receive products have any questions about the product, can look for us,we will help you deal with the the first time,to your satisfaction. |

Exhibition

Certificate

Company profile

ZheJiang Arrow Machinery Co., Ltd.is a company specializing in R&D, production, sales, application promotion of food engineering projects. As 1 of the largest scaled food processing equipment &whole plant engineering problem solvers in China, machines served for more than 970 companies, export to 116 countries, area, more than 20 years engineering team, we recognize that quality equals value, aims to create a great future together with global customers.

FAQ

1. Q: How about Arrow Machinery?

R: ZheJiang Arrow Machinery Co., Ltd. is a High-Tech company. Our firm is composed of a strong

team which has substantial experience in R&D, manufacture, technique and sales service and has

specialized in extruder industry for 10 years,leading screw barrel manufacturer in China.

2. Q:What’s Arrow machinery’s capacity?

R:Company is in strict accordance with CE and ISO9001 quality certification system.There are over 200

models of extruders and spare parts.

3. Q:What’s the delivery time?

R:For regular size, we have finished stock and semi-finished stock, 2 weeks max enough

for customized, normally within 20days .

4. Q:How about the gearbox quality and price?

R: top quality in China with competitive price and globle after-sale service

5. Q:what’s the life time and guarantee buy from Arrow machinery ?

R: 3~5years life time for nitriding ones and bimtallic ones will be longer

One year min. Guarantee.

6.Q:Where is Arrow Machinery factory and how to reach there?

R:NO.47 Chengbohu Road, Xihu (West Lake) Dis. District,HangZhou City, China. You can take the train or plane to HangZhou and we can pick you up.

7.Q:How to contact with you?

R:just reply to me if have any question.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Three-Ring |

| Samples: |

US$ 3600/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Common Problems and Troubleshooting for Worm Gearboxes

Worm gearboxes, like any mechanical component, can experience various issues over time. Here are some common problems that may arise and possible troubleshooting steps:

- Overheating: Overheating can occur due to factors such as inadequate lubrication, excessive loads, or high operating temperatures. Check lubrication levels, ensure proper ventilation, and reduce loads if necessary.

- Noise and Vibration: Excessive noise and vibration may result from misalignment, worn gears, or improper meshing. Check for misalignment, inspect gear teeth for wear, and ensure proper gear meshing.

- Leakage: Oil leakage can be caused by damaged seals or gaskets. Inspect seals and gaskets, and replace them if necessary.

- Reduced Efficiency: Efficiency loss can occur due to friction, wear, or misalignment. Regularly monitor gearbox performance, ensure proper lubrication, and address any wear or misalignment issues.

- Backlash: Excessive backlash can affect precision and accuracy. Adjust gear meshing and reduce backlash to improve performance.

- Seizure or Binding: Seizure or binding can result from inadequate lubrication, debris, or misalignment. Clean the gearbox, ensure proper lubrication, and address misalignment issues.

- Worn Gears: Worn gear teeth can lead to poor performance. Regularly inspect gears for signs of wear, and replace worn gears as needed.

- Seal Wear: Seals can wear over time, leading to leakage and contamination. Inspect seals regularly and replace them if necessary.

If you encounter any of these problems, it’s important to address them promptly to prevent further damage and maintain the performance of your worm gearbox. Regular maintenance, proper lubrication, and addressing issues early can help extend the lifespan and reliability of the gearbox.

How to Calculate the Input and Output Speeds of a Worm Gearbox?

Calculating the input and output speeds of a worm gearbox involves understanding the gear ratio and the principles of gear reduction. Here’s how you can calculate these speeds:

- Input Speed: The input speed (N1) is the speed of the driving gear, which is the worm gear in this case. It is usually provided by the manufacturer or can be measured directly.

- Output Speed: The output speed (N2) is the speed of the driven gear, which is the worm wheel. To calculate the output speed, use the formula:

N2 = N1 / (Z1 * i)

Where:

N2 = Output speed (rpm)

N1 = Input speed (rpm)

Z1 = Number of teeth on the worm gear

i = Gear ratio (ratio of the number of teeth on the worm gear to the number of threads on the worm)

It’s important to note that worm gearboxes are designed for gear reduction, which means that the output speed is lower than the input speed. Additionally, the efficiency of the gearbox, friction, and other factors can affect the actual output speed. Calculating the input and output speeds is crucial for understanding the performance and capabilities of the worm gearbox in a specific application.

What is a Worm Gearbox and How Does It Work?

A worm gearbox, also known as a worm gear reducer, is a mechanical device used to transmit rotational motion and torque between non-parallel shafts. It consists of a worm screw and a worm wheel, both of which have helical teeth. The worm screw resembles a threaded cylinder, while the worm wheel is a gear with teeth that mesh with the worm screw.

The working principle of a worm gearbox involves the interaction between the worm screw and the worm wheel. When the worm screw is rotated, its helical teeth engage with the teeth of the worm wheel. As the worm screw rotates, it translates the rotational motion into a perpendicular motion, causing the worm wheel to rotate. This perpendicular motion allows the worm gearbox to achieve a high gear reduction ratio, making it suitable for applications that require significant speed reduction.

One of the key features of a worm gearbox is its ability to provide a high gear reduction ratio in a compact design. However, due to the sliding nature of the meshing teeth, worm gearboxes may exhibit higher friction and lower efficiency compared to other types of gearboxes. Therefore, they are often used in applications where efficiency is not the primary concern but where high torque and speed reduction are essential, such as conveyor systems, elevators, automotive steering systems, and certain industrial machinery.

editor by CX 2024-03-26

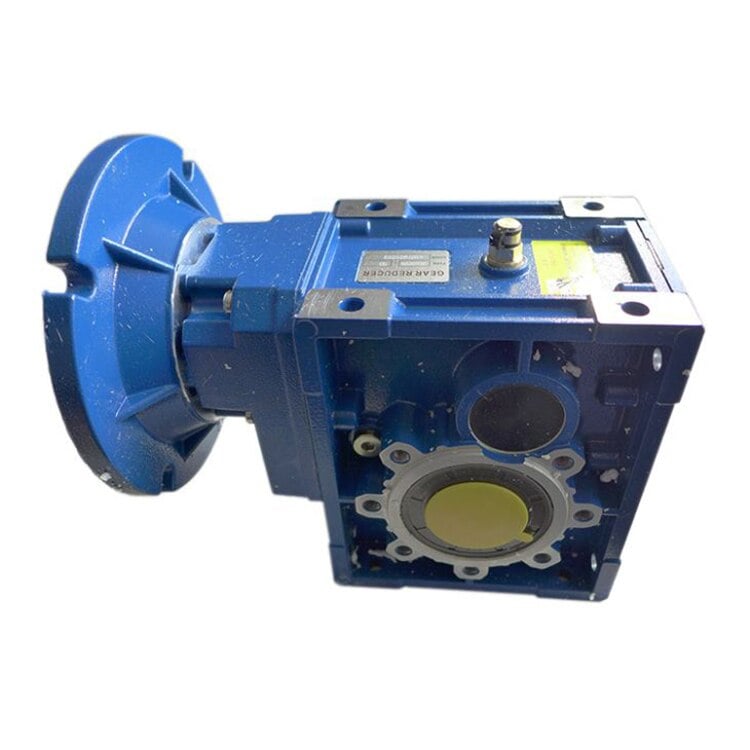

China high quality RV Series Aluminium Worm Speed Reduction Gear Gearbox Reducer differential gearbox

Product Description

Worm Gear Speed Reducer Unit

|

Input Configurations |

Double or single input shaft (NRV) |

|

PAM / IEC motor input shaft with circle or square flange (NMRV) |

|

|

Output Configurations

|

Double or single output shaft |

|

Output flange |

Main Feature

The gearbox can rotate in both directions operate and contains 1 oil filling at delivery. you will benefit from its high quality and a short delivery time.

Specification

|

Model |

Motor Input Flange (circle) |

Transmission Ratio |

Power (kw) |

Ratio (i) |

Nominal Torque (Nm) |

|||||||||||||||

|

PAM / IEC |

Internal Dia. |

Dis. Between Diagonal Screw Holes |

External Dia. |

Width of Key Slot |

5 |

7.5 |

10 |

15 |

20 |

25 |

30 |

40 |

50 |

60 |

80 |

100 |

||||

|

N |

M |

P |

E |

Diamter of Input Shaft |

||||||||||||||||

|

NMRV25 |

56B14 |

50 |

65 |

80 |

3 |

9 |

– |

9 |

– |

0.06 |

7.5-60 |

2.6-14 |

||||||||

|

NMRV30 |

63B5 |

95 |

115 |

140 |

4 |

11 |

– |

0.06-0.18 |

7.5-80 |

2.6-14 |

||||||||||

|

63B14 |

60 |

75 |

90 |

|||||||||||||||||

|

56B5 |

80 |

100 |

120 |

3 |

9 |

– |

||||||||||||||

|

56B14 |

50 |

65 |

80 |

|||||||||||||||||

|

NMRV40 |

71B5 |

110 |

130 |

160 |

5 |

14 |

– |

0.09-0.37 |

7.5-100 |

11-53 |

||||||||||

|

71B14 |

70 |

85 |

105 |

|||||||||||||||||

|

63B5 |

95 |

115 |

140 |

4 |

11 |

|||||||||||||||

|

63B14 |

60 |

75 |

90 |

|||||||||||||||||

|

56B5 |

80 |

100 |

120 |

3 |

– |

9 |

||||||||||||||

|

NMRV50 |

80B5 |

130 |

165 |

200 |

6 |

19 |

– |

0.12-0.75 |

7.5-100 |

21-89 |

||||||||||

|

80B14 |

80 |

100 |

120 |

|||||||||||||||||

|

71B5 |

110 |

130 |

160 |

5 |

14 |

– |

||||||||||||||

|

71B14 |

70 |

85 |

105 |

|||||||||||||||||

|

63B5 |

95 |

115 |

140 |

4 |

– |

11 |

||||||||||||||

|

NMRV63 |

90B5 |

130 |

165 |

200 |

8 |

24 |

– |

0.25-1.5 |

7.5-100 |

56-166 |

||||||||||

|

90B14 |

95 |

115 |

140 |

|||||||||||||||||

|

80B5 |

130 |

165 |

200 |

6 |

19 |

– |

||||||||||||||

|

80B14 |

80 |

100 |

120 |

|||||||||||||||||

|

71B5 |

110 |

130 |

160 |

5 |

– |

14 |

||||||||||||||

|

71B14 |

70 |

85 |

105 |

|||||||||||||||||

|

NMRV75 |

100/112B5 |

180 |

215 |

250 |

8 |

– |

28 |

– |

0.55-4 |

7.5-100 |

90-269 |

|||||||||

|

100/112B14 |

110 |

130 |

160 |

|||||||||||||||||

|

90B5 |

130 |

165 |

200 |

8 |

24 |

– |

||||||||||||||

|

90B14 |

95 |

115 |

140 |

|||||||||||||||||

|

80B5 |

130 |

165 |

200 |

6 |

– |

19 |

||||||||||||||

|

80B14 |

80 |

100 |

120 |

|||||||||||||||||

|

71B5 |

110 |

130 |

160 |

– |

– |

14 |

||||||||||||||

|

NMRV90 |

100/112B5 |

180 |

215 |

250 |

8 |

– |

28 |

– |

0.55-4 |

7.5-100 |

101-458 |

|||||||||

|

100/112B14 |

110 |

130 |

160 |

|||||||||||||||||

|

90B5 |

130 |

165 |

200 |

8 |

24 |

– |

||||||||||||||

|

90B14 |

95 |

115 |

140 |

|||||||||||||||||

|

80B5 |

130 |

165 |

200 |

6 |

– |

19 |

||||||||||||||

|

80B14 |

80 |

100 |

120 |

|||||||||||||||||

|

NMRV110 |

132B5 |

230 |

265 |

300 |

10 |

– |

38 |

– |

1.1-7.5 |

7.5-100 |

242-660 |

|||||||||

|

132B14 |

130 |

165 |

200 |

– |

||||||||||||||||

|

100/112B5 |

180 |

215 |

250 |

8 |

28 |

– |

||||||||||||||

|

90B5 |

130 |

165 |

200 |

– |

24 |

|||||||||||||||

|

90B14 |

95 |

115 |

140 |

– |

||||||||||||||||

|

80B5 |

130 |

165 |

200 |

– |

19 |

|||||||||||||||

|

NMRV130 |

132B5 |

230 |

265 |

300 |

10 |

– |

38 |

– |

2.2-7.5 |

7.5-100 |

333-1596 |

|||||||||

|

132B14 |

130 |

165 |

200 |

– |

||||||||||||||||

|

100/112B5 |

180 |

215 |

250 |

8 |

– |

28 |

||||||||||||||

|

90B5 |

130 |

165 |

200 |

– |

– |

24 |

||||||||||||||

|

90B14 |

95 |

115 |

140 |

|||||||||||||||||

|

NMRV150 |

160B5 |

250 |

300 |

350 |

12 |

– |

42 |

– |

2.2-15 |

7.5-100 |

570-1760 |

|||||||||

|

132B5 |

230 |

265 |

300 |

10 |

– |

38 |

– |

|||||||||||||

|

132B14 |

130 |

165 |

200 |

– |

||||||||||||||||

|

100/112B5 |

180 |

215 |

250 |

8 |

– |

28 |

||||||||||||||

Company profile

Scenario

Packing

FAQ

Q1: I want to buy your products, how can I pay?

A: You can pay via T/T(30%+70%), L/C ,D/P etc.

Q2: How can you guarantee the quality?

A: One year’s warranty against B/L date. If you meet with quality problem, please send us pictures or video to check, we promise to send spare parts or new products to replace. Our guarantee not include inappropriate operation or wrong specification selection.

Q3: How we select models and specifications?

A: You can email us the series code (for example: RC series helical gearbox) as well as requirement details, such as motor power,output speed or ratio, service factor or your application…as much data as possible. If you can supply some pictures or drawings,it is nice.

Q4: If we don’t find what we want on your website, what should we do?

A: We offer 3 options:

1, You can email us the pictures, drawings or descriptions details. We will try to design your products on the basis of our

standard models.

2, Our R&D department is professional for OEM/ODM products by drawing/samples, you can send us samples, we do customized design for your bulk purchasing.

3, We can develop new products if they have good market. We have already developed many items for special using successful, such as special gearbox for agitator, cement conveyor, shoes machines and so on.

Q5: Can we buy 1 pc of each item for quality testing?

A: Yes, we are glad to accept trial order for quality testing.

Q6: How about your product delivery time?

A: Normally for 20’container, it takes 25-30 workdays for RV series worm gearbox, 35-40 workdays for helical gearmotors.

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | B3,B6,B7,B8,V5,V6 |

| Layout: | Coaxial |

| Gear Shape: | Cylindrical Gear |

| Step: | Single-Step |

| Customization: |

Available

| Customized Request |

|---|

What is a Worm Gearbox and How Does It Work?

A worm gearbox, also known as a worm gear reducer, is a mechanical device used to transmit rotational motion an

How to Install and Align a Worm Reducer Properly

Proper installation and alignment of a worm reducer are crucial for ensuring optimal performance and longevity. Follow these steps to install and align a worm reducer:

- Preparation: Gather all the necessary tools, equipment, and safety gear before starting the installation process.

- Positioning: Place the worm reducer in the desired location, ensuring that it is securely mounted to a stable surface. Use appropriate fasteners and mounting brackets as needed.

- Shaft Alignment: Check the alignment of the input and output shafts. Use precision measurement tools to ensure that the shafts are parallel and in line with each other.

- Base Plate Alignment: Align the base plate of the reducer with the foundation or mounting surface. Ensure that the base plate is level and properly aligned before securing it in place.

- Bolt Tightening: Gradually and evenly tighten the mounting bolts to the manufacturer’s specifications. This helps ensure proper contact between the reducer and the mounting surface.

- Check for Clearance: Verify that there is enough clearance for any rotating components or parts that may move during operation. Avoid any interference that could cause damage or performance issues.

- Lubrication: Apply the recommended lubricant to the worm reducer according to the manufacturer’s guidelines. Proper lubrication is essential for smooth operation and reducing friction.

- Alignment Testing: After installation, run the worm reducer briefly without a load to check for any unusual noises, vibrations, or misalignment issues.

- Load Testing: Gradually introduce the intended load to the worm reducer and monitor its performance. Ensure that the reducer operates smoothly and efficiently under the load conditions.

It’s important to refer to the manufacturer’s installation guidelines and specifications for your specific worm reducer model. Proper installation and alignment will contribute to the gearbox’s reliability, efficiency, and overall functionality.

d torque between non-parallel shafts. It consists of a worm screw and a worm wheel, both of which have helical teeth. The worm screw resembles a threaded cylinder, while the worm wheel is a gear with teeth that mesh with the worm screw.

The working principle of a worm gearbox involves the interaction between the worm screw and the worm wheel. When the worm screw is rotated, its helical teeth engage with the teeth of the worm wheel. As the worm screw rotates, it translates the rotational motion into a perpendicular motion, causing the worm wheel to rotate. This perpendicular motion allows the worm gearbox to achieve a high gear reduction ratio, making it suitable for applications that require significant speed reduction.

One of the key features of a worm gearbox is its ability to provide a high gear reduction ratio in a compact design. However, due to the sliding nature of the meshing teeth, worm gearboxes may exhibit higher friction and lower efficiency compared to other types of gearboxes. Therefore, they are often used in applications where efficiency is not the primary concern but where high torque and speed reduction are essential, such as conveyor systems, elevators, automotive steering systems, and certain industrial machinery.

editor by

Worm Gearboxes in Conveyor Systems: Benefits and Considerations

Worm gearboxes play a crucial role in conveyor systems, offering several benefits and considerations for their effective integration:

- Space Efficiency: Worm gearboxes have a compact design, making them suitable for applications with limited space, such as conveyor systems.

- High Reduction Ratios: Worm gearboxes can achieve high reduction ratios in a single stage, allowing for slower conveyor speeds without sacrificing torque.

- Self-Locking: Worm gearboxes have inherent self-locking properties, preventing the conveyor from moving when the motor is not actively driving it.

- Directional Control: Worm gearboxes facilitate directional control, enabling the conveyor to move forward or reverse as needed.

- Low Noise: Worm gearboxes often produce lower noise levels compared to other gearbox types, contributing to quieter conveyor operation.

However, there are also considerations to keep in mind when using worm gearboxes in conveyor systems:

- Efficiency: Worm gearboxes may have lower mechanical efficiency compared to some other gearbox types, leading to energy losses.

- Heat Generation: Worm gearboxes can generate more heat due to sliding contact between the worm and gear, necessitating proper cooling mechanisms.

- Lubrication: Proper lubrication is critical to prevent wear and ensure efficient operation. Regular maintenance is required to monitor lubrication levels.

- Load and Speed: Worm gearboxes are well-suited for applications with high torque and low to moderate speed requirements. They may not be optimal for high-speed conveyors.

Before integrating a worm gearbox into a conveyor system, it’s important to carefully consider the specific requirements of the application, including load, speed, space constraints, and efficiency needs. Consulting with gearbox experts and manufacturers can help ensure the right choice for the conveyor’s performance and longevity.

CX 2023-08-22

China factory 7.5~100 Ratio CZPT Shaft Output Small 1: 50 Ratio Reduction Unit Speed Reducer Gear Combination Transmission Gearbox Worm Gear Box with Good quality

Product Description

7.5~100 Ratio CZPT Shaft Output Small 1: 50 Ratio Reduction Unit Speed reducer Gear Combination Transmission Gearbox Worm Gear box

Products Description

NMRV worm gearbox reducer is a commodity with sophisticated design and continuous improvements, its main features are made of high quality aluminum alloy, light weight and non-rusting, larget output toque, smooth running and low noise, high radiating efficiency, good looking apprearance, derable service life, small volume and suitable for all mounting positions.

Feature

1. Mad of high-quality aluminum alloy,light weight and non-rusting

2. Large output torque

3. Smooth in running and low in noise,can work long time in dreadful conditions.

4. High in radiating efficiency.

5. Good-looking in appearance,durable in service life and small in volume.

6. Suitable for omnibearing installation.

Click here to contact us for discounts!

|

Model |

NMRV571, NMRV030, NMRV040, NMRV050, NMRV063, NMRV075, NMRV090, NMRV110, NMRV130, NMRV150 |

|

Ratio |

5,7.5,10,15,20,25,30,40,50,60,80,100 |

|

Output Torque |

1.8-1760Nm |

|

Application |

Machinery Industry |

|

Input Speed |

900-2800RPM |

|

Output Speed |

10-250RPM |

|

Material |

Housing: Size 25-110 Is Aluminum Alloy, Size 110-150 Is Cast-Iron |

|

Worm Wheel: ZCuSn10Pb1 |

|

|

Worm:20Cr |

|

|

Pinion:Tin Bronze |

|

|

Output Shaft: Steel-45# |

|

|

IEC Flange |

IEC Standard Flange Or On Customer Request |

Related products

Company Profile

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Steel |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) What are the Noise Levels Associated with Worm Gearboxes?The noise levels associated with worm gearboxes can vary depending on several factors, including the design, quality, operating conditions, and maintenance of the gearbox. Here are some key points to consider:

It’s important to note that while worm gearboxes can produce some noise due to the nature of gear meshing, proper design, maintenance, and operation can significantly reduce noise levels. If noise is a concern for your application, consulting with gearbox manufacturers and experts can provide insights into selecting the right gearbox type and implementing measures to minimize noise. | |

|---|

Preventing Backlash in a Worm Gearbox

Backlash in a worm gearbox can lead to reduced accuracy, positioning errors, and decreased overall efficiency. Here are steps to prevent or minimize backlash:

- High-Quality Components: Use high-quality worm gears and worm wheels with tight manufacturing tolerances. Precis

Diagnosing and Fixing Oil Leakage in a Worm Gearbox

Oil leakage in a worm gearbox can lead to reduced lubrication, increased friction, and potential damage to the gearbox components. Here’s a step-by-step process to diagnose and fix oil leakage:

- Inspect the Gearbox: Perform a visual inspection of the gearbox to identify the source of the leakage. Check for oil stains, wet spots, or oil pooling around the gearbox.

- Check Seals and Gaskets: Inspect the seals, gaskets, and O-rings for any signs of wear, cracks, or damage. These components are common points of leakage.

- Tighten Bolts and Fasteners: Ensure that all bolts, screws, and fasteners are properly tightened. Loose fasteners can create gaps that allow oil to escape.

- Replace Damaged Seals: If you find damaged seals or gaskets, replace them with new ones. Use seals that are compatible with the operating conditions and lubricant.

- Check Breather Vent: A clogged or malfunctioning breather vent can cause pressure buildup inside the gearbox, leading to leakage. Clean or replace the breather vent if necessary.

- Examine Shaft Seals: Check the shaft seals for wear or damage. If they’re worn out, replace them with seals of the appropriate size and material.

- Use Proper Lubricant: Ensure that you’re using the correct lubricant recommended for the gearbox. Using the wrong type of lubricant can cause leaks.

- Apply Sealants: In some cases, applying a suitable sealant to the joints and connections can help prevent leaks. Follow the manufacturer’s instructions for proper application.

- Monitor Leakage: After addressing the issues, monitor the gearbox for any signs of continued leakage. If leakage persists, further investigation may be required.

- Regular Maintenance: Implement a regular maintenance schedule that includes checking seals, gaskets, and other potential leakage points. Timely maintenance can prevent future leakage issues.

If you’re unsure about diagnosing or fixing oil leakage in a worm gearbox, consider consulting with a professional or gearbox manufacturer to ensure proper resolution.

ion components will help reduce backlash.

- Proper Meshing: Ensure the worm gear and worm wheel are properly aligned and meshed. Improper meshing can lead to increased backlash.

- Preload: Applying a small amount of preload to the worm gear can help reduce backlash. However, excessive preload can increase friction and wear.

- Anti-Backlash Mechanisms: Consider using anti-backlash mechanisms, such as spring-loaded systems or adjustable shims, to compensate for any inherent backlash.

- Lubrication: Proper lubrication can reduce friction and play a role in minimizing backlash. Use a lubricant that provides good film strength and reduces wear.

- Maintenance: Regularly inspect and maintain the gearbox to identify and address any changes in backlash over time.

It’s important to strike a balance between reducing backlash and maintaining smooth operation. Consulting with gearbox experts and following manufacturer guidelines will help you optimize your worm gearbox’s performance while minimizing backlash.

editor by CX 2023-08-14

China NMRV 30 7.5-100 ratio Aluminum alloy Die casting 0.06-0.18kw gear reduction worm speed reducer gearbox definition

Guarantee: 1 a long time

Applicable Industries: Developing Materials Outlets, Manufacturing Plant, Building works , Energy & Mining

Weight (KG): 1.3 KG

Custom-made assist: OEM

Gearing Arrangement: Worm

Output Torque: 2.6-24N.M

Enter Speed: 1400rpm

Output Pace: seventeen.5-186.7rpm

Item title: NMRV Worm Equipment Reducer

Model: NMRV30

Material: aluminum alloy Die casting

Color: Blue

Type: Worm Gear Velocity Reducer Gearbox

Quality: 1 Year Certain

Gears Type: Metallic Equipment

Motor sort: Suitable

Customization: Assistance Drawing Customization

Port: HangZhou or ZheJiang

Why Decide on Us Solution Display Product Paramenters

| Product identify | NMRV Worm Equipment Reducer |

| Warranty | 1 a long time |

| Applicable Industries | Building Material Outlets, Production Plant, Building functions , Vitality & Mining |

| Weight (KG) | 1.3KG |

| Customized support | OEM |

| Gearing Arrangement | Worm |

| Output Torque | 2.6-24N.M |

| Input Speed | 1400rpm |

| Output Pace | 17.5-186.7rpm |

| Place of Origin | ZHangZhoug, China |

| Brand Identify | Jiahuang |

| Model | NMRV30 |

| Material | aluminum alloy Die casting |

| Color | Blue |

| Type | Worm Equipment Velocity Reducer Gearbox |

| Quality | 1 12 months Assured |

| Gears Fashion | Metal Equipment |

| Motor type | Suitable |

| Customization | Support Drawing Customization |

Types of Gearboxes

There are several types of gearboxes. Some are known as helical gear reducers, while others are called planetary gearboxes. The article also discusses Continuously Variable Transmission (CVT) and helical gear reducer. If you are interested in purchasing a new gearbox, make sure to read our articles on these different types. If you are confused, consider reading our articles on planetary gearboxes and helical gear reducers.

planetary gearbox

The planetary gearbox has several advantages. Its compact design and light weight allows it to transmit high torques while remaining quiet. The gears are connected to one another through a carrier, which is typically fixed and helps transmit torques to the output shaft. Its planetary structure arrangement also reduces backlash and provides high rigidity, which is important for quick start and stop cycles and rotational direction change. Depending on the design and performance desired, planetary gearboxes are categorized into three main types:

The type of planetary gears used in a given application determines the overall cost of the unit. Manufacturers offer a range of prices, and they can help you determine which gearbox is right for your needs. You should also ask a manufacturer for the cost of a planetary gearbox. By asking about price and specs, you can avoid wasting money and time on a planetary gearbox that does not perform up to its potential.

A planetary gearbox is probably installed in your new car’s automatic transmission. For more information, consult your owner’s manual or call the dealer’s service department. This type of gearbox is more complex than other types of gearboxes, so if you don’t know much about them, do an internet search for “planetary gearbox.”

The teeth of a planetary gearbox are formed by the stepping motion of two gears: the sun gear and the inner ring. The sun gear is the input, while the planetary gears rotate around the sun gear. Their ratio depends on the number of teeth and the space between the planets. If you have a 24 tooth sun gear, the planetary gears’ ratio will be -3/2. The sun gear is also attached to the axle.

Another advantage of a planetary gear system is that it can generate high torques. The load is shared among multiple planet gears. This makes the gears more resilient to damage. A planetary gearbox can be as high as 332,000 Nm, and can be used in vehicles and industrial applications requiring medium to high torque. A planetary gear system is a great alternative to a traditional transmission. So, how does it work?

helical gearbox

The main difference between the helical gearbox and the spur gear is the center distance between the teeth. The helical gearbox has a larger pitch circle than the spur gear and thus requires a radial module. In addition, the two types of gears can only be made with the same tooth-cutting tool as the spur gear. However, the helical gearbox is more efficient in terms of production costs.

The helical gearbox is a low-power consumption, compact type of gearbox that is used for a wide range of industrial applications. They are highly durable and withstand high loads with utmost efficiency. The helical gearbox can be manufactured in cast steel and iron for small and medium units. This type of gearbox is also commonly used for crushers, conveyors, coolers, and other applications that need low power.

The helical gear has many advantages over the spur gear. It produces less noise. It has less friction and is less likely to wear out. It is also quieter than spur gears. This is because multiple teeth are in mesh. Because the teeth are in mesh, the load is distributed over a larger area, resulting in a smoother transition between gears. The reduction in noise and vibration reduces the risk of damaging the gear.

The helical gear’s axial excitation force is obtained using a linearized equation of motion in the rotational direction. The damping coefficient of the equation is 0.07. The helical gear is made up of a steel shaft with a diameter of 20 mm and a 5 mm thick aluminum plate. The stiffness of the bearing is 6.84 x 107 N/m. The damping force of the plate is 2,040 kg/m2/s.

The worm gearbox has a better efficiency ratio than the helical one, but it is less efficient in low-ratio applications. In general, worm gearboxes are more efficient than helical gearboxes, although there are some exceptions to this rule. A helical gearbox is better for applications that require high torque. It may also be more economical in the long run. If you are considering a helical gearbox, consider the advantages it has over worm gearboxes.

helical gear reducer

A helical gear reducer for a machine’s gearbox is an integral component of the drive system. This unit amplifies torque and controls speed and, therefore, compliments the engine by rotating slower than the engine’s input shaft. A helical gear reducer is a compact gearbox component that is used in industrial applications. A variety of sizes is available to suit various machine configurations. The following sections will discuss some of the different types available.

Designed by experts and engineers, a helical gear reducer is a surprisingly small and light gear that satisfies the needs of many machine applications. It features a large transmission torque, a low starting and running speed, and a fine classification of transmission ratios. A helical gear reducer is lightweight and easily connected to other gears, and it features a high technical content.

In order to avoid errors and poor performance, regular maintenance is a must. The proper lubrication of the gear reducer can minimize failures, errors, and poor performance. Every gear reducer manufacturer sells a suitable lubricant, which must match the properties of the machine’s drive mechanism. It is also advisable to check the lubrication regularly to avoid any deterioration of the unit’s performance.

While the worm gearbox may be better for applications where torque is high, the helical gear reducer offers greater efficiency at lower cost. Although worm gearboxes may be cheaper initially, they are less effective at higher ratios. Even if the worm gear is more expensive to buy, it still offers 94% efficiency, which makes it more cost-effective. There are some significant advantages to both types of gearboxes.

The main advantage of a helical gear reducer over a spur gear is its smoother operation. Unlike spur gears, which have teeth that are straight, helical gears have angled teeth that gradually engage with each other. This helps ensure that the gear does not grind or make excessive noise when it turns. Additionally, they are less commonly used in automation and precision machinery. They are often used in industrial applications.

Continuously variable transmission

A Continuously Variable Transmission (CVT) is an automatic transmission that can run through a vast number of gears. Unlike a standard automatic transmission, it can run at any speed, even at a low rev. The CVT is also capable of running at infinitely low gears. Its basic function is to provide different torque ratios to the engine. In addition to delivering power, CVTs have other benefits.

One of the major advantages of a CVT is its simplicity. Its simplicity translates into fewer moving parts, which means less maintenance. The CVT’s simplicity also means that it can handle a wide variety of different types of road conditions and driving styles. In addition to being a great alternative to a traditional automatic transmission, CVTs can be used on many other types of vehicles, including tractors, snowmobiles, motor scooters, and power tools.

A CVT is much smoother than a conventional automatic transmission. It never has to hunt for a gear. It also responds well to throttle inputs and speed changes. Both of these technologies are available on many modern vehicles, including the Nissan Rogue and Mazda CX-5. It’s important to note that each of these transmissions has its pros and cons. So, if you’re looking for a car with a CVT, make sure to read the reviews. They’ll help you decide which transmission is right for you.

Another advantage of a CVT is its fuel efficiency. Many cars now feature CVTs, and they’re becoming increasingly popular with automakers. In addition to fuel efficiency, most cars with CVTs also have a smoother ride. There’s no more sudden downshifts or gear hunting. This makes driving a lot easier. And, the added benefits of smoother driving make CVTs the ideal choice for many drivers.

Although a CVT is more common among Japanese car manufacturers, you’ll find CVTs on European car models as well. The Mercedes-Benz A-Class, B-Class, and Megane are some examples of vehicles that use this technology. Before making a decision, consider the reliability of the model in question. Consumer Reports is a good resource for this. It also offers a history of use and reliability for every type of car, including the Honda Accord.

editor by czh

China Good quality Helical Gear Reducer High Speed Planetary Reduction Gearbox for Industrial Using with Hot selling

Product Description

Planetary Series High Electricity Equipment Box

Housing is manufactured of cast iron,which enhance its rigidity and anti-vibration.

Sun and plant gears are processed by cementite and hardening,gears are procedures by grinding,which increase the performance and life time of the gearbox.

Input manner:coaxial input,helical equipment enter,bevel-helical gear enter.

Output mode:inside involute spline,hollow shaft with shrink disk,exterior involute spline,reliable shaft with flat important.

Mounting manner:Horizonal vertical,torque-arm.

P series sizes 9~34 transmission phase:2~3 ratio:25~4000

Ratio will be more substantial in combination with H,R,K sequence.

RFQ

Q:Are you investing company or company?

A: We are maker with more than twenty years’ encounter.

Q: How long is your shipping time?

A: Usually it is in 10 times if the items are in inventory, for merchandise made as for every purchase, it is in 35 days soon after affirmation of get.

Q: How prolonged must I hold out for the opinions right after I send the enquiry?

A: Normally within twelve several hours.

Q: What info should I give you to confirm the item?

A: Product/Dimensions, Transmission Ratio, Velocity, Shaft instructions & Buy amount and many others.

Q: Hong long is your product guarantee?

A: We provide 12 months warranty from departure day of the goods.

Q: What is your payment phrases? T/T a hundred% in CZPT for quantity much less than USD10000.-, thirty% T/T in CZPT , harmony prior to cargo for quantity over USD10000.

If you have any other questions, make sure you come to feel free to contact us beneath:

HOW TO Get in touch with US?

Deliver your Inquiry Specifics in the Beneath, click on “Send” Now!

Gearboxes go by numerous different names, like equipment drives, pace reducers, equipment reducers, velocity reducers, and gear motors. All conditions are employed interchangeably when referring to inline gear reducers. Our inventory consists of a extensive selection of equipment reducers for higher speed, substantial precision apps with enter speeds up to 4000 RPM.

Gearboxes can be utilised in a variety of fields of comprehensive processing, agriculture, chemical processing, oil and gasoline, power transmission and distribution methods, logistics, warehousing and other industries. Equipment reducers are usually utilized the place greater torque and/or reduced rotational speeds are essential, or if power needs to be transmitted at alternating angles, such as in correct-angle motors. It can also adjust the path of rotation, as nicely as clockwise and counterclockwise. EP provides a comprehensive range of gear reducers with right angle worms and substantial effectiveness possibilities. Electrical Equipment Aluminum items are a lightweight and sturdy different to present day forged iron and metal designs and can be stocked or custom produced to your exact specifications. EP gearboxes are light-weight and durable, aluminum worm gearboxes are developed for tight spaces, like challenging-to-put in OEM patterns as nicely as mobile equipment. Eccentric reducers are available as compact aluminum or forged iron inline reducers with seal life rankings from 15HP (aluminum) to 40HP (cast iron). In addition to our common and modified standard items, our engineers will operate with you to design and develop custom made solutions for numerous generate systems to go well with your application wants.

China best RV Series Nmrv 025-125 Gearbox Aluminum Cast Iron Wheel Reduction Transmission Drive Speed Reducer Worm Gear Box with high quality

Merchandise Description

Rv Series Nmrv 571-one hundred twenty five gearbox Aluminum Cast Iron Wheel Reduction Transmission Push Speed Reducer Worm Equipment Box

Goods Attributes

1. Manufactured of large-top quality aluminum alloy,light-weight bodyweight and non-rusting

2. Big output torque

three. Sleek in managing and minimal in sounds,can function long time in dreadful problems.

4. Higher in radiating performance.

5. Excellent-searching in physical appearance,tough in service existence and small in quantity.

6. Suitable for omnibearing set up.

Features of Worm Reducer /Gearbox

one.Widespread mounting dimensions.

two.Aluminum and forged iron housing.

three.Worm and worm wheel transmission.

four.Compact framework and gentle-bodyweight.

5.Vast assortment of equipment.

Benefits of Worm Gearbox / Reducer

1.Unique housing style will distinguish you from other competition.

two.Multiple choice for oil seal.

3.The dimensions can be custom-made according to customer’s needs.

|

Model No |

NMRV571, NMRV030, NMRV040, NMRV050, NMRV063, NMRV075, NMRV090, NMRV110, NMRV130, NMRV150 |

|

Ratio |

five,7.5,10,fifteen,twenty,25,30,forty,fifty,sixty,80,one hundred |

|

Material |

Housing: Size 25-a hundred and ten Is Aluminum Alloy, Dimension one hundred ten-one hundred fifty Is Cast-Iron |

|

Worm Wheel: ZCuSn10Pb1 |

|

|

Worm:20Cr |

|

|

Pinion:Tin Bronze |

|

|

Output Shaft: Steel-45# |

|

|

Variety |

Worm Equipment Velocity Reducer / Gearbox / Reductor |

|

Colour |

Tailored Coloration |

|

Packing |

Carton, Honey Comb Carton, Wood Situation with Picket Pallet |

|

Use |

Industrial Machine, Foods Stuff, Ceramics, Chemical, Packing, Dyeing, Wooden Working, Glass, and so forth. |

|

Flange |

IEC common flange or custom-made dimensions |

|

Housing Content |

Aluminum&Forged iron |

|

Measurement |

11 measurements(WMRV25~WMRV185) |

|

Energy |

.06~22 KW |

|

Nominal torque |

≤2548 N.m |

|

Ratio |

5~one hundred |

Connected Products

Organization Details

The expression “gearbox” is utilized to refer to any unit that connects a motor to a equipment and is made up of a series of gears, also acknowledged as a equipment established. It receives the main input speed from the motor and alterations it to a various output velocity employing its gears. Various types and mixtures of gears serve certain reasons. The sorts of gears found in gearboxes include spur gears, bevel gears, helical gears, helical gears and worm gears. The performance efficiency of a gearbox is represented by the gearbox ratio, which is the ratio of the speed of the enter supply to the velocity of the output resource

Gearboxes go by several distinct names, like gear drives, speed reducers, equipment reducers, pace reducers, and equipment motors. All phrases are employed interchangeably when referring to inline gear reducers. Our inventory involves a extensive selection of gear reducers for substantial speed, substantial precision purposes with enter speeds up to 4000 RPM.

China Hot selling Automatic Power Transmission Gear Reducer Planetary Gearbox Speed Reduction for Gear Motors with Free Design Custom

Merchandise Description

Technical services:

- According to the appropriate parameters offered by the consumer, the SIGRINER engineering software is utilized to produce the movement load curve diagram of the system products to get the corresponding parameters and derive the motion load curve. Intuitively show essential parameters and load indexes in the transmission technique to assist buyers have out sensible structural style.

- SIGRINER offers a motor databases from 500 servo motor companies around the world

Buyer instruction:

We are honored to provide you with our utilized computing and transmission style knowledge. We can give appropriate training according to your requirements. We can supply relevant coaching according to your wants.

Certain

| STAGE | 2 | |||||||||

| Gear ratio | i | twenty | 20 | 25 | 30 | forty | 50 | 70 | 70 | |

| Rated output torque (one thousand moments is authorized in gear box) |

T 2N | Nm | 19 | 19 | 22 | 20 | 17 | 22 | 19 | fourteen |

| In.lb | 177 | 168 | 195 | 177 | 150 | 195 | 168 | 124 | ||

| T 2NOt | Nm | 1.5xNOM.Output/ 1.5 instances rated output torque | ||||||||

| In.lb | ||||||||||

| Rated input RPM (T2N, 20ºC environment temperature) b | N 1n | rpm | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 |

| Max. Enter RPM | N 1max | rpm | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 |

| Max.backlash | J t | arcmin | PBMD40≤5 ARCMIN | |||||||

| Max.radical drive | F 2AMAX | N | 300 | |||||||

| ibf | 68 | |||||||||

| Max.axial drive | F 3RMAX | N | 180 | |||||||

| ibf | 40.five | |||||||||

| Function lifestyle | L h | hr | ≥20000 | |||||||

| Totally loaded effectiveness | η | % | 95 | |||||||

| Environment temperature | ºC | -fifteen to 40 | ||||||||

| F | 5 to 104 | |||||||||

| Allowable highest temperature of shell |

ºC | +90 | ||||||||

| F | 194 | |||||||||

| Lubrication | Life Lubrication | |||||||||

| Rotation course | Input/output with exact same direction | |||||||||

| Safety class | IP65 | |||||||||

| Installation direction | Any/ any direction | |||||||||

| Operating noise (i=10 and n1=3000rpm no-load) |

Lpa dB(A) | ≤65 | ||||||||

| Moment of inertia | J1 | Kg.cm² | .three | .3 | .3 | .3 | .three | .3 | .three | .three |

| 10-3in.lb.s2 | .three | .3 | .three | .three | .three | .three | .three | .three | ||

Sector application

- We offer fast source and robust help all in excess of the planet by means of a complete sales and support community

- With years of prosperous expertise, our authoritative experts provide market place-major consulting providers for various industrial sectors

- Robotics, automation and manipulator engineering

A range of servo gearboxes and mechanical transmission systems, from economical to high-stop types can be applied to a variety of robots and their auxiliary axes, these kinds of as transmission shafts and station handle gadgets

Printing device

Modern gearbox ensures balance, synchronization accuracy and prolonged-time period precision even at large speeds

The ideal solution for large-good quality printing processes and other continuous duty purposes

Choice: built-in sensor for checking paper tension and comparable parameters

Appropriate angle gearboxes (worm and planetary gears) are sturdy and can be utilised for 90° turns. An inline reducer (parallel shaft and planetary) is an excellent matching motor with substantial enter speeds, or when equipment motor effectiveness is crucial. Get in touch with our technical revenue employees to support figure out which transmission solution is ideal for you.

Gear reducers are also referred to as reducers. Mechanical components, by possibly of these two names, are created to lessen the energy transferred amongst the motor and the machine between the rotational speeds (revolutions per moment). The reducer efficiently minimizes the rotational pace developed by the motor, therefore managing the pace at which the device runs and escalating the torque developed by the motor. Multiplying the torque produced by the motor raises the machine’s available energy – a approach acknowledged as “mechanical dominance”. In a larger context, equipment reducers are essentially tools utilized to boost the effectiveness of equipment operation.

in Rome Italy sales price shop near me near me shop factory supplier Wpa Standard Gearbox Reduction of Speed Reducer Design manufacturer best Cost Custom Cheap wholesaler

Every single procedure, every section, each and every function in EPG is demanded to be completed 1 stage adhering to one more, meticulously and cautiously, from substance choice, reformation to producing add-ons, from parts warmth remedy to automated assembly, from good quality management to product inspection and testing and from get dealing to following income services. In this way, our merchandise have ongoing to gain marketplace acceptance and customers pleasure above the earlier couple of a long time. Our solution assortment includes all types of helical gear, spur equipment, bevel gear, equipment rack, worm equipment, sprockets,chains, bearings.

WPA stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd EPTT reduction of velocity EPTT design

Our EPTT has numerous items for your deciding on and we can make as for every your drawing or sample to fulfill your EPTT request

one. Massive output torque

2. Risk-free, reputable, cost-effective and durable

3. Stable EPTT, silent operation

4. Substantial carrying capacity

five. Substantial modularization design and style, may equip with various outer EPTT enter conveniently. Very same EPTT type might equip with numerous EPTT motor. It is effortless to comprehend the mixture and junction in between each and every EPTT type

6. EPTT ratio: Fine division, broad scope. The merged EPTT sort may type extremely large EPTT ratio, i. E. Output really minimal rotary pace.

7. Kind of installation: The place to be installed is not limited.

eight. Substantial power, compact the box body of large power solid iron, EPTT and EPTT shaft adapts the fuel carbonization, quenching and fine grinding procedure, for that reason the bearing ability of device volume is higher.

nine. EPTT existence: UnEPTTthe situation of proper type chosen(incXiHu (West Lake) Dis.Hu (West Lake) Dis. picking suitable operation parament ) normal operation and maintenance, the daily life if primary components velocity EPTT(apart from wearing parts)should not be less than 20000 several hours. The sporting areas incEPTT lubricating oil, oil seal and bearing.

ten. Lower sound: Because primary areas of pace EPTT are processed, and tested critically, for that reason the noise of pace EPTT is lower.

eleven.Our EPTT box have achieved the EPTT global level, can substitute the exact same sort of products EPTTed.

Firm Details

HangEPTT EPTT Sector Co., Ltd. is a EPTTized provider of a complete variety of EPTTs, sprockets, EPTTs, EPTT racks, v belt pulley, timing pulley, V-belts, couplings, EPTTd elements and so on.

Owing to our sincerity in giving best provider to our clientele, understXiHu (West Lake) Dis.Hu (West Lake) Dis. of your wants and overriding sense of duty toward filling purchasing needs, we have acquired the EPTT of purchasers worldwide. Getting gathered valuable experience in cooperating with foreign consumers, our items are promoting properly in the American, European, South American and Asian marketplaces.Our items are manufactured by modern day computerized EPTTry and gear. Meanwhile, our merchandise are made according to higher top quality stXiHu (West Lake) Dis.Hu (West Lake) Dis.rds, and complying with the global EPTT stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd standards.

With a lot of years’ expertise in this line, we will be EPTTed by our benefits in competitive price tag, a single-time supply, prompt reaction, on-hand engineering support and excellent after-product sales services.

Furthermore, all our creation processes are in compliance with ISO9001 stXiHu (West Lake) Dis.Hu (West Lake) Dis.rds. We also can layout and make non-stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd products to satisfy customers’ EPTT demands. EPTT and credit score are the bases that make a corporation alive. We will provide greatest companies and higher top quality goods with all sincerity. If you want any details or samples, make sure you get in touch with us and you will have our shortly reply.

China manufacturer & factory supplier for HangZhou in Coimbatore India EPG WPLF Series Servo Planetary Gearbox Speed Reducer Reduction Gearbox With high quality best price & service

corrosion- and dress in-resistant coiled tubing injector roller chain assemblies for the oil and gas industries. Offered in single and double pitch travel chain varieties with a variety of measurements and electricity ranking. Attributes consist of zinc-nickel and non-hexavalent chromate protecting exterior coating, electrochemically bonded, and interference suit protect plates.More importantly, we make particular components according to equipped drawings/samples and warmly welcome OEM inquiries.

Overview

Quick Specifics

- Relevant Industries:

-

Manufacturing Plant

- GearingIn our income software we offer you regular and broad-angle PTO push shafts. Relating to the customers’ wants there are distinct dimensions, lengths and safety aspects (clutches) obtainable. Arrangement:

-

Helical

- Model Quantity:

-

WPF40, WPF60, WPF90, WPF120, WPF160, WPF180

Offer Ability

- Supply Potential:

- five hundred Established/Sets for each Month

Packaging & Shipping and delivery

- Packaging Specifics

- wooden scenario

- Port

- Shanghai , Ningbo , Shenzhen , Tianjin ect

On the web Customization

Product Information

Solution Description

| Gearing Arrangement | Planetary |

| Location of Origin | China |

| Brand name Name | 202001EPG |

| China | Zhejiang |

| Design Number | WPF40, WPF60, WPF90, WPF120, WPF160, WPF180 |

Solution Show

Solution Screen

Associated Items

EK sequence helical- …

ER sequence helical …

CHC TRC HELICAL GE …

CompanyInfo

Firm Profile

Solution Approach

Creation Process

Certifications

Certifications

consumer-outlined

Cargo & Payment

Our Advantages

A: YoIndustrial Reducers EPG Travel offers two kinds of industrial gearbox, covering regular obligation by way of to heavier obligation and severe obligation purposes observed in some of the world’s most inhospitable mining sites.ur inquiry connected to our items or rates will be replied in 24 hrs.

B: Defense of your sales spot, suggestions of design and all your personal data.

C: Ideal top quality and aggressive value.

……

faq

FAQ

1) How can I place get?

A: You can get in touch with us by e mail about your buy specifics, or area get on line.

2) How can I spend you?

A: After you verify our PI, we will ask for you to spend. T/T (HSBC bank) and Paypal, Western Union are the most normal ways we are making use of.

……

EPG major creation is of farming 15-500 horsepower tractor supporting equipment, mechanical cultivation, harvesting equipment and equipment.